Sony STARVIS vs. STARVIS 2 — A Technical Review for Industrial Vision

Engineers selecting low-light cameras for embedded vision or 24/7 industrial monitoring often start with Sony’s STARVIS family. This article unpacks the architectural differences between STARVIS and STARVIS 2, examines IMX385 and IMX335 strengths/limits, outlines likely 2026 sensor directions, and closes with four concrete U.S./EU deployments. Tone: technical, vendor-neutral, outcome-driven.

1) STARVIS vs. STARVIS 2: What Changed?

STARVIS (Gen-1) introduced back-illuminated (BSI) CMOS with large effective pixel apertures for color imaging at starlight levels. It optimized read noise, QE (quantum efficiency), and dual-conversion gain (DCG) for wide dynamic scenes without sacrificing SNR.

STARVIS 2 (Gen-2) refines the stack:

- Improved low-light SNR at the same lux via lower input-referred read noise and better microlens efficiency (higher angular response → less shading with wide lenses).

- Wider dynamic range through expanded conversion gain ladder and more flexible HDR compositing (2/3-frame and line-by-line modes).

- Motion-robust HDR: shorter individual exposures and smarter knee points reduce ghosting on conveyors, vehicles, or swinging tools.

- System friendliness: lower power per lux, better NIR response options, and tighter FPN calibration → less ISP effort for clean blacks at 0.001–0.01 lux.

Bottom line: If your scene mixes very dark + localized glare (steel, ports, tunnels) or you need wide-angle lenses without corner darkening, STARVIS 2 provides measurable headroom. For stable factory lighting, classic STARVIS remains a strong value.

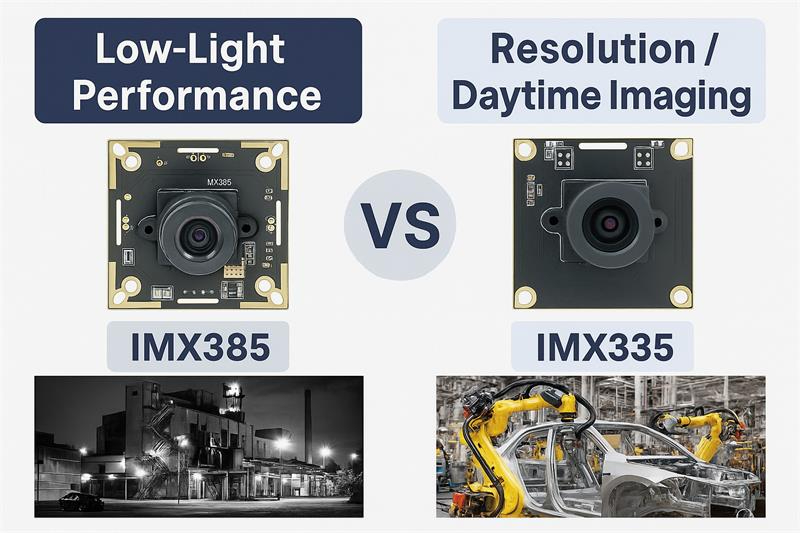

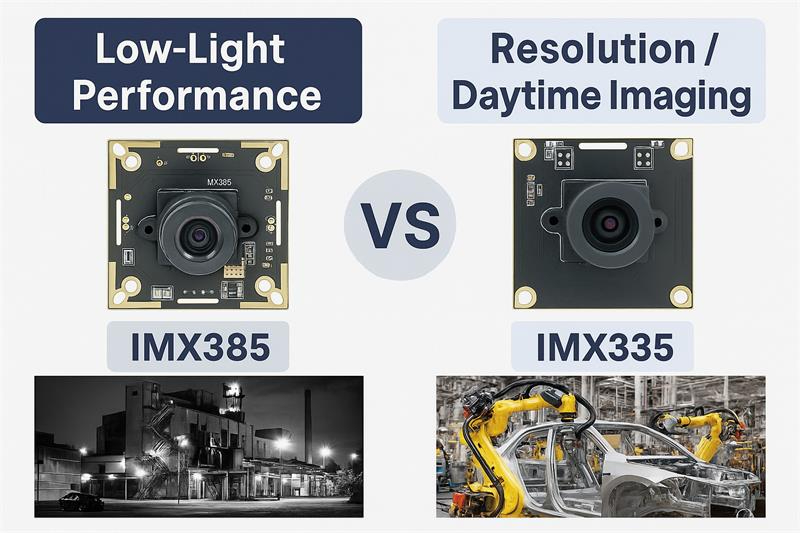

2) IMX385 vs. IMX335 — Choosing the Right Tool

|

Attribute

|

IMX385 (STARVIS)

|

IMX335 (STARVIS)

|

|

Native Resolution

|

2MP (1920×1080)

|

5MP (2592×1944)

|

|

Optical Format

|

1/2″ (large pixel)

|

1/2.8″

|

|

Pixel Pitch

|

≈3.75 µm (light bucket)

|

≈2.0 µm (detail density)

|

|

Typical Strength

|

Ultra-low-light color, stable SNR, low motion blur at modest gain

|

Higher detail + HDR, better for measurement/analytics

|

|

Bandwidth to Host

|

Lower (easier on USB/ISP)

|

Higher (needs USB3.0 and efficient encode)

|

|

Lenses Often Used

|

2.8/6/8 mm for security & general monitoring

|

No-distortion M12/C-mount for AOI & metrology

|

|

Best Fits

|

Perimeter/night monitoring, yards, substations, marine

|

Inspection, ANPR context, dashboards/HMI cameras

|

IMX385 pros

- Big pixels → clean color at 0.001–0.01 lux.

- Runs well with shorter exposure (less blur on moving belts/AGVs).

- Great when PC/NVR compute is limited (fewer pixels to push).

IMX385 cons

- 2MP caps fine-detail analytics (tiny labels, micro-defects).

- For wide areas you may need more cameras to hit px/m targets.

IMX335 pros

- 5MP gives 2.5× linear detail vs. 1080p; enables OCR/barcode, small defect checks, and better digital zoom.

- With correct optics (no-distortion), geometry-accurate measurements are feasible.

- “Starlight” builds can still perform well in low light; AF variants handle near-far workflows.

IMX335 cons

- Smaller pixels → at the very lowest lux you’ll raise gain or add IR fill to freeze motion.

- Higher data rate → mind USB3.0 throughput and host encode settings.

Selection heuristic

- Night-first security / energy yards / ports → IMX385.

- Inspection / analytics / measurement (esp. Great Lakes manufacturing) → IMX335 (no-distortion or AF).

3) Pipeline & ISP Notes (USB/HDMI modules)

- USB 3.0/UVC: for PCs/edge boxes (Windows/Linux/Jetson). Use YUY2/MJPEG/H.264 wisely; cap exposure for moving scenes.

- HDR strategy: start with DCG on; enable multi-exposure HDR only when highlights clip (welding, tunnel portals).

- Lens + FOV: publish px/m tables per distance. For license plates or small defects target ≥150–300 px/m; general detection ≥40–60 px/m.

- Lighting: STARVIS minimizes illuminators; add 850 nm IR only to freeze motion at 1/120–1/250 s.

4) 2026 Outlook — Likely Sony Directions (Engineering Predictions)

Not commitments—technical expectations based on STARVIS 2 trends:

- Larger-format STARVIS 2 at 2–5 MP with >120 dB DR without heavy motion artifacts, targeting traffic and robotics.

- NIR-boosted starlight SKUs (enhanced 850/940 nm QE) to share optics with covert security/industrial IR lines.

- Stacked BSI with on-chip HDR/temporal NR that reduces host ISP cost for USB/HDMI modules.

- High-efficiency rolling shutters with global-reset or short-exposure blending to narrow the gap to true global-shutter in robotics while retaining STARVIS sensitivity.

- Power-optimized variants for fanless edge devices and battery-borne platforms (UAVs, mobile testers).

What this means for buyers: expect cleaner HDR, better NIR, and lower system power, while keeping STARVIS’ hallmark color at starlight.

5) Why STARVIS USB/HDMI Modules Win vs. Alternatives

Compared with typical low-light offerings from other CMOS vendors, STARVIS/STARVIS 2 modules generally provide:

- Higher color fidelity at sub-lux (less forced monochrome).

- Mature HDR with lower ghosting, easing deployment in mixed lighting.

- Broader lens ecosystem (no-distortion, AF, tele, wide) and stable UVC interoperability.

- Lower total cost of imaging: fewer illuminators, simpler ISP, and faster bring-up on standard PCs or embedded x86/ARM.

When global shutter is mandatory (fast metrology, high-speed robotics), consider pairing STARVIS context cameras with dedicated GS sensors. For most surveillance and general AOI, STARVIS’ rolling shutter yields better low-light SNR per watt.

6) Four Concrete Deployments (U.S. & Europe)

- Great Lakes (Indiana, Steel Mill AOI)

- Module: IMX335 no-distortion USB3.0

- Task: Surface defect screening post-pickling.

- Why: 5MP + calibrated optics meet 200 px/m while HDR tames overhead glare; USB3 streams directly to an industrial PC for inline analytics.

- Texas (Refinery Perimeter, Night Security)

- Module: IMX385 USB (starlight) with 6–8 mm optics

- Task: Color identification at <0.01 lux without large IR arrays.

- Outcome: Lower lighting power; exposure 1/60–1/120 s keeps vehicle motion sharp.

- Florida (Port Crane Operations & Yard Safety)

- Module: IMX335 Starlight Autofocus

- Task: One camera for near spreader locks and distant lane monitoring.

- Outcome: AF reduces operator refocus; HDR resists dazzling vessel lighting.

- Germany (Automotive Battery Line, Alignment Aid)

- Module: IMX335 no-distortion USB3.0

- Task: FPC alignment and weld bead presence check.

- Outcome: Accurate geometry for analytics; 5MP enables OCR/barcode in the same station.

7) Practical Spec & Tuning Cheatsheet

- IMX385 security: start 1/30–1/60 s, gain ≤24 dB, gamma ≈0.9, DCG on; add low IR only if motion blur persists.

- IMX335 inspection: lock exposure to line speed; for shiny parts enable HDR with short bright exposure; use no-distortion lens and publish calibration.

- AF variant: define AF windows; disable continuous AF during encode if CPU is tight—use “touch-to-focus” zones from the HMI.

8) Takeaways

- Choose IMX385 when night visibility and stable color at very low lux dominate.

- Choose IMX335 when detail density & measurement accuracy matter, or you need one camera to do detection + analytics (AF option where ranges vary).

- STARVIS 2 extends dynamic range, wide-angle corner quality, and motion-robust HDR—useful in tunnels, steel, ports, and robotics.

- With USB/HDMI modules, integration time and TCO drop: standard I/O, simpler ISP, fewer illuminators, and faster field commissioning.

Need a matched module?

We build IMX385 and IMX335 USB/HDMI modules (no-distortion and autofocus options) with custom optics, enclosures, and firmware for industrial OEMs. If you have target px/m, distance, and lux, we’ll return a lens + exposure + HDR plan and sample within days.

Let’s engineer the right STARVIS camera for your line, yard, port, or plant.