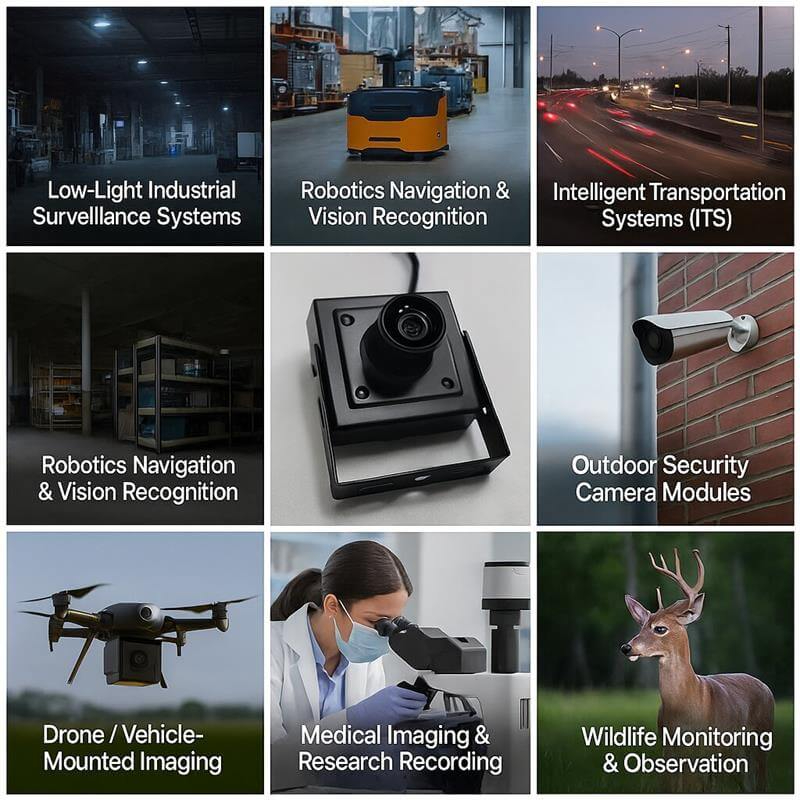

If you are a project leader, engineer, or product manager in Europe or North America, you’ve likely faced this dilemma:

You know your project requires a STARVIS USB camera module to achieve high-quality imaging, but the market is flooded with options. There are too many sensor models—IMX335 camera module, IMX307, IMX385, IMX415, IMX462—and every supplier seems to promise the same thing. How do you select the right sensor? How do you ensure your supplier can deliver not only the hardware but also the SDK, integration support, and customization your project requires?

The fear of making the wrong choice—choosing the wrong sensor, wrong interface, or wrong supplier—can delay projects or even cause them to fail.

This blog provides a clear, professional roadmap: how to select the right Sony STARVIS sensor, what the custom development process looks like, and why working with Shenzhen Novel Electronics Limited ensures long-term project success.

Before even considering datasheets, project leaders must clearly define:

These questions determine whether you prioritize sensitivity, resolution, cost, or latency.

Engineers often search “IMX335 vs IMX307” or “IMX335 vs IMX415” to weigh performance vs. cost. Below is a quick comparison of some popular sensors.

|

Sensor |

Resolution |

Pixel Size |

Low-Light Performance |

HDR Support |

Best Application |

|

IMX307 |

2MP |

2.9µm |

Strong, cost-effective |

Yes |

Entry-level surveillance, IoT cameras |

|

IMX335 |

5MP |

2.0µm |

Excellent, IMX335 low light performance (starlight-level) |

Yes (~120 dB) |

Robotics, smart city, machine vision |

|

IMX385 |

2MP |

3.75µm |

Superb starlight capability |

Yes |

Night security, ITS, traffic cameras |

|

IMX415 |

8MP (4K) |

1.45µm |

Good, but smaller pixels |

Yes |

High-res industrial inspection |

|

IMX462 |

2MP |

2.9µm |

Outstanding NIR + low light |

Yes |

AI IoT, scientific imaging, robotics vision |

Conclusion:

This is where Shenzhen Novel Electronics Limited adds value: we don’t just sell hardware, we guide customers from concept to mass production.

The first step in customizing a USB3.0 camera with starlight vision is requirements gathering. Our team conducts in-depth discussions, asking questions such as:

This ensures we design a camera that is not only technically compatible but also aligned with your project’s cost and schedule.

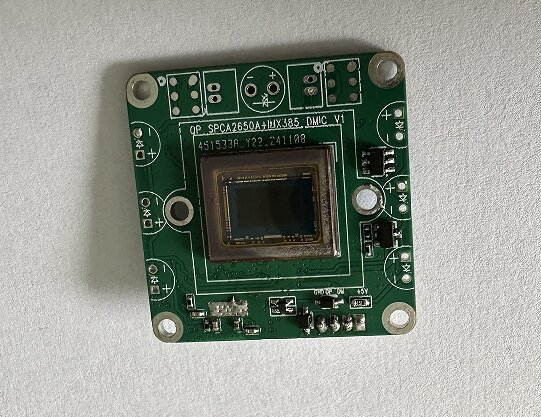

Once requirements are clear, our engineers begin PCB design and hardware layout.

This is where many suppliers fall short. We specialize in firmware optimization and SDK support, ensuring:

For engineers, this means you’re not left with a “black box”—you get a development-ready camera module.

Prototypes are manufactured and undergo strict testing:

Once validated, we move into scaled production.

For years, Shenzhen Novel Electronics Limited has been the OEM/ODM partner of choice for industrial clients in Europe and North America.

Selecting the right STARVIS USB camera module is a critical step for any industrial vision or robotics project. The Sony IMX335 camera module delivers a unique balance of resolution, starlight-level low light performance, and HDR capability, making it one of the most versatile 5MP Starvis sensors on the market.

By working with Shenzhen Novel Electronics Limited, you gain a partner that understands both the technical depth and the industrial realities of camera module integration.