How to Choose the Right USB Camera Module for Your Industrial Vision System

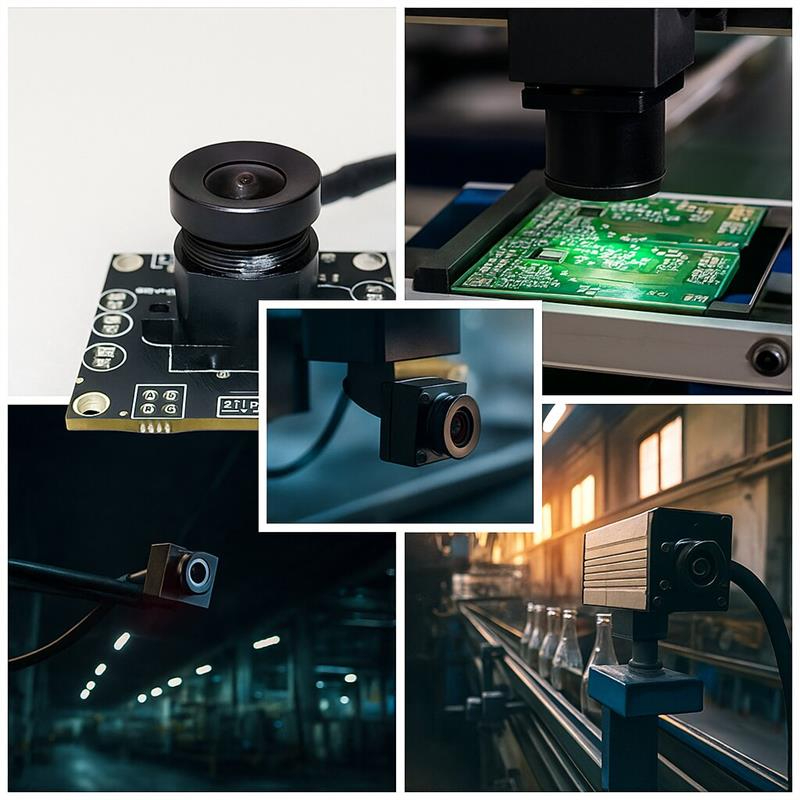

Industrial vision systems are the silent partners powering modern manufacturing – ensuring quality control, guiding robots, reading codes, and inspecting products with superhuman precision. At the heart of many of these systems lies a critical component: the USB camera module. Choosing the right one isn't just about grabbing any webcam; it's about selecting a robust, reliable sensor engineered for demanding industrial environments.

Selecting poorly can lead to downtime, inaccurate results, and costly replacements. Here’s your guide to making an informed decision:

1. Define Your Application's Core Requirements:

* Resolution: What level of detail is needed? Tiny surface defects require high resolution (e.g., 5MP, 8MP, 12MP+), while simple presence detection might only need VGA or HD (720p/1080p). Remember, higher resolution often means slower frame rates and larger data streams.

* Frame Rate (FPS): How fast is the object moving? High-speed processes (like bottling lines or electronics assembly) demand high frame rates (60 FPS, 120 FPS, or even higher) to avoid motion blur and capture every critical moment.

* Field of View (FOV): How much area needs to be captured? This depends on the working distance and the size of the target object. Consider lens options (fixed focus, varifocal) and sensor size.

* Object Characteristics: What are you inspecting? Reflective surfaces, low-contrast features, or tiny components might demand specific sensor technologies (Global vs. Rolling Shutter) or advanced features like High Dynamic Range (HDR) or specific lighting integration needs.

2. Prioritize Industrial Ruggedness & Reliability:

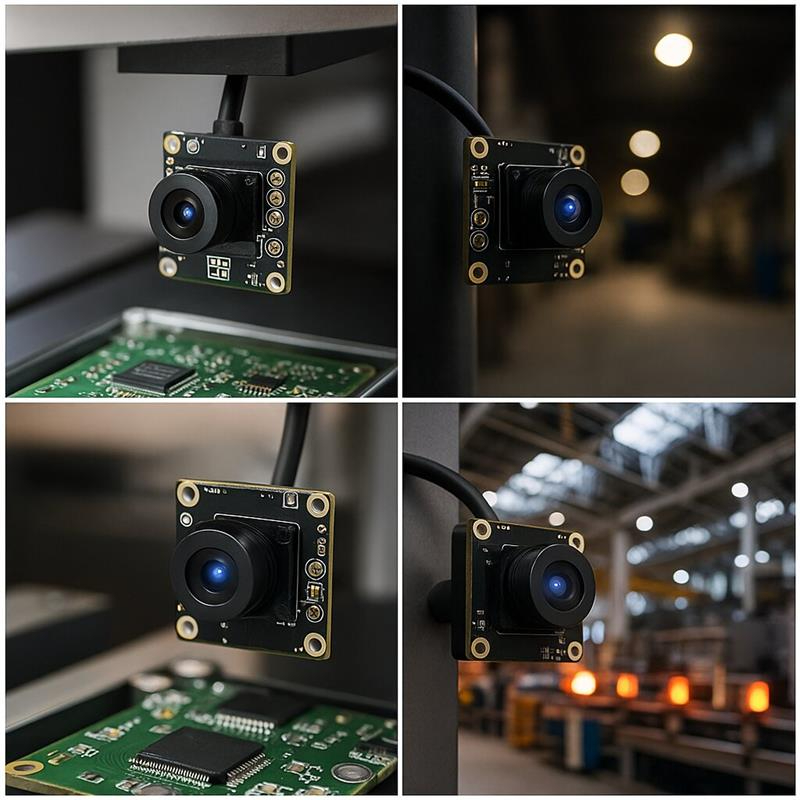

* Build Quality: Look for robust metal housings, not plastic. Industrial environments have vibration, shock, dust, and potential impacts.

* Operating Temperature Range: Factories can be hot near machinery or cold in warehouses. Ensure the camera's specified range (-10°C to 50°C, -20°C to 70°C, etc.) exceeds your environment's extremes.

* Ingress Protection (IP Rating): Protection against dust and liquids is crucial. IP65/IP67 ratings are common benchmarks for industrial cameras, signifying dust-tightness and resistance to water jets or temporary immersion.

* EMI/EMC Compliance: Industrial settings are electrically noisy. Ensure the camera meets relevant EMC standards (like CE, FCC) to avoid interference and ensure stable operation.

* Locking Connectors: Essential! Standard USB ports can vibrate loose. Look for cameras with screw-locking USB connectors (typically USB 3.0 Type-B or USB-C) and often locking power connectors if used.

3. USB Interface: Speed Matters (USB3 Vision is Key!)

* USB 3.x (USB 3.0/3.1/3.2 Gen 1): This is the minimum standard for industrial vision. It offers speeds up to 5 Gbps, sufficient for most HD and many multi-megapixel applications at moderate frame rates. Crucially, look for cameras supporting the USB3 Vision standard. This provides:

* Plug-and-Play Interoperability: Standardized communication protocol works seamlessly with major vision software libraries (Halcon, OpenCV, VisionPro, Common Vision Blox) and frameworks.

* GigE Vision-like Features: GenICam compliance ensures standardized access to camera features and controls.

* Reliability: Robust error handling and recovery mechanisms designed for industrial use.

* USB 2.0: Generally avoid for new industrial systems except for very low-resolution, low-speed tasks. Its 480 Mbps bandwidth severely limits resolution and frame rate capabilities. Prone to latency and instability under load.

* Cable Length: USB 3.x is typically limited to ~3-5 meters without active extension or repeaters. Plan your system layout accordingly. Industrial-grade, shielded cables are a must.

4. Sensor & Image Quality Considerations:

* Sensor Type (CMOS): Dominates the industrial space. Pay attention to:

* Shutter Type: Global Shutter is preferred for moving objects as it captures the entire image simultaneously, eliminating motion blur. Rolling Shutter is cheaper but can cause skew on fast-moving objects.

* Pixel Size: Larger pixels generally perform better in low light but require a larger sensor for the same resolution.

* Sensitivity/Low-Light Performance: Measured in lux or quantum efficiency. Critical if ambient light is low or inconsistent. Look for low minimum illumination ratings.

* Image Signal Processor (ISP): Onboard processing for tasks like auto-exposure, auto-white balance, noise reduction, and color correction. A good ISP significantly improves out-of-the-box image quality and consistency.

5. Software, Drivers & Compatibility:

* Operating System Support: Ensure drivers and SDKs are available for your system OS (Windows, Linux variants - especially Ubuntu LTS, real-time OSes).

* Vision Software Compatibility: Verify seamless integration with the software you plan to use (e.g., Halcon, OpenCV, LabVIEW, custom C++/Python/Python). USB3 Vision/GenICam compliance makes this far easier.

* SDK & Documentation: A well-documented Software Development Kit (SDK) and clear examples are invaluable for efficient integration and troubleshooting. Check the manufacturer's support resources.

6. Industrial Certifications & Longevity:

* Certifications: Look for relevant industrial and safety certifications beyond basic EMC (e.g., UL, CSA, RoHS, REACH).

* Long-Term Availability: Industrial systems often have long lifecycles. Choose a manufacturer known for long-term product support and availability (often 5+ years). Avoid consumer-grade modules with short lifecycles.

* Warranty & Support: Industrial warranties are typically longer (2-3+ years). Check the manufacturer's technical support reputation.

7. Lens Mount & Optics:

* Mount Type: The most common industrial mount is C-mount, offering a vast selection of interchangeable lenses (wide-angle, telephoto, macro, etc.). S-mount (M12) is smaller and used for compact, fixed-lens modules. CS-mount is less common industrially.

* Lens Selection: Factor in the cost and availability of suitable lenses for your FOV and working distance requirements. Consider fixed focus vs. varifocal vs. motorized zoom if needed.

Key Takeaway Checklist:

Prototyping is Paramount:

Never finalize a camera choice based solely on specs. Always prototype! Test the specific camera module with your actual setup – lighting, optics, target objects, software, and environmental conditions. This is the only way to truly validate performance.

Investing Wisely:

Choosing the right USB industrial camera module is an investment in the reliability, accuracy, and longevity of your vision system. By carefully evaluating your application needs against the rugged specifications and standards required for the factory floor, you can select a module that delivers consistent, high-quality results day in and day out, becoming a dependable workhorse in your automated processes. Take the time to choose wisely – your production line will thank you.