In today’s industrial and embedded vision markets, the demand for high-resolution, low-latency, and low-light-capable imaging solutions is stronger than ever. The Sony IMX678 CMOS sensor, paired with a 4mm lens delivering a 95-degree field of view in a 38×38mm HDMI camera module, offers a perfect balance of clarity, flexibility, and ease of integration for engineers and product managers working on robotics, automation, inspection systems, and embedded vision projects.

This combination is not just another camera module — it’s a specialized tool designed to perform in environments where image quality, speed, and adaptability directly determine operational success.

The Sony IMX678 is an 8.4MP STARVIS 2 CMOS sensor capable of capturing 3840 × 2160 (4K) resolution video with exceptional detail. When paired with the 4mm lens and a 95° field of view, it achieves an ideal balance between coverage and detail:

For applications like conveyor belt inspection or AGV navigation, the 95° field of view ensures that both close-range and medium-range objects remain visible and measurable.

The STARVIS 2 back-illuminated pixel architecture provides superior light sensitivity. The IMX678 can deliver clear, low-noise images even in illumination levels below 0.004 lux, making it perfect for:

Compared to many competing CMOS sensors of the same resolution, the IMX678’s 2.0µm pixel size allows more light capture per pixel, resulting in cleaner images and better color reproduction in challenging conditions.

Industrial and field environments often have extreme lighting contrasts — from bright reflective metal parts to dark shadowed areas. The IMX678 handles this with its native multi-exposure HDR/WDR, preserving detail in both highlights and shadows without motion blur or ghosting.

This makes it ideal for:

Unlike MIPI or USB-based solutions that may require software integration and driver tuning, the HDMI output of this module enables direct connection to industrial monitors, DVR systems, or vision processing units:

For factories, this means engineers and QC inspectors can instantly view live video without additional PC setup, speeding up deployment and reducing downtime.

Space is often at a premium in industrial machines, robotic arms, and embedded systems. The 38×38mm PCB makes it easy to integrate the module into:

Its small footprint combined with the wide-angle lens allows installation in tight spaces without sacrificing field coverage.

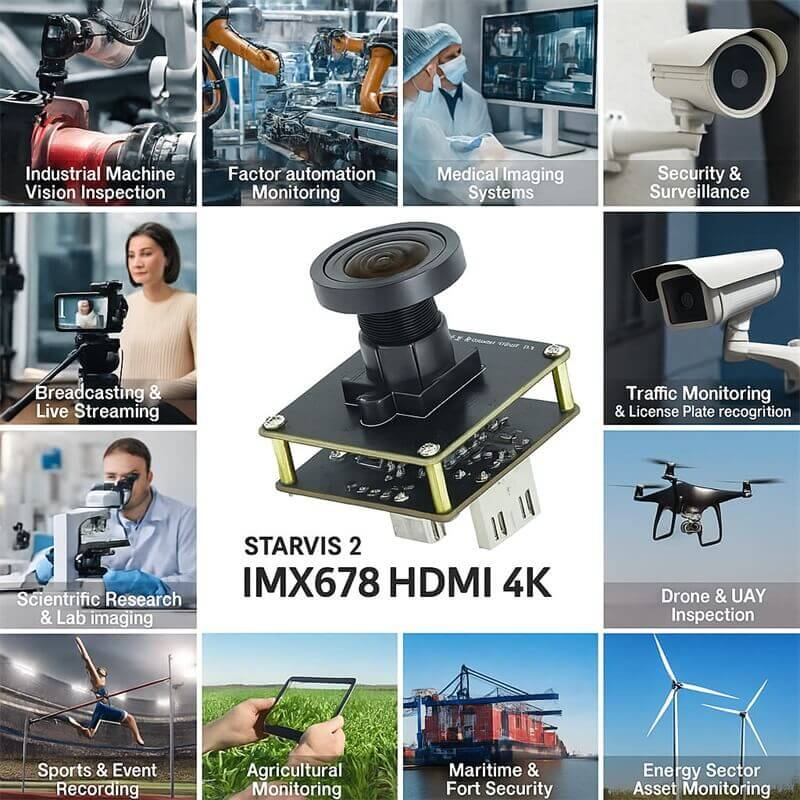

Industrial Inspection:

Robotics & Automation:

Medical & Lab Imaging:

Security & Monitoring:

For engineers, system integrators, and vision specialists in the industrial, robotics, medical, and security sectors, the Sony IMX678 HDMI camera module with 4mm lens and 95° FOV offers a plug-and-play imaging solution that excels in low light, handles complex lighting, and delivers 4K detail in real time.

Its combination of STARVIS 2 low-light sensitivity, high dynamic range, and direct HDMI connectivity makes it a competitive choice in high-value, mission-critical vision applications.