Case Study: How Thermal Imaging Cameras Reduce Downtime in Oil Refineries

In the oil & gas sector, unplanned equipment failures can cost millions of dollars per day in lost production, not to mention safety risks and environmental exposure. Refineries in Europe and the United States operate 24/7 under extreme conditions—heat, pressure, vibration, and corrosive environments—that make predictive maintenance a strategic priority.

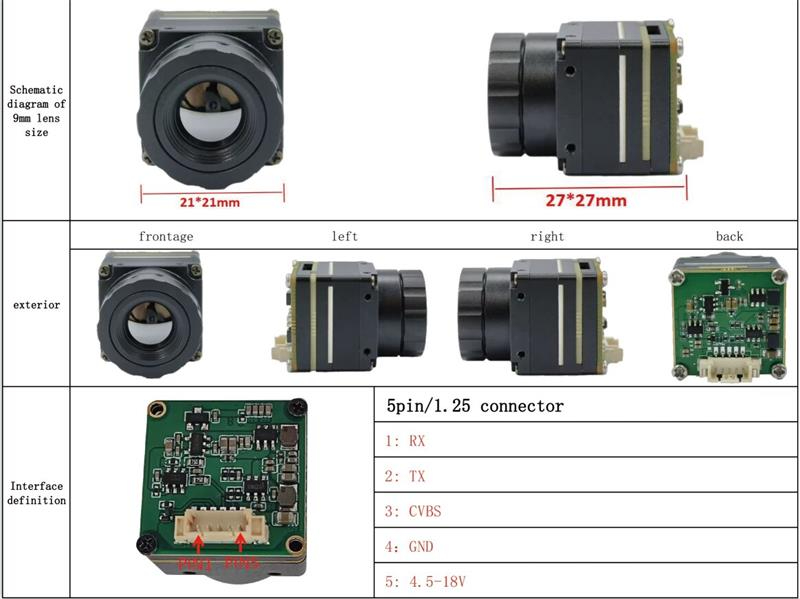

Traditional inspection tools often fail to detect subtle early-stage issues such as abnormal heat signatures, pipeline leaks, or electrical hotspots. This is where micro thermal imaging camera modules (256 × 192, 384 × 288, 640 × 480 resolutions) play a transformative role, enabling non-contact, real-time monitoring that identifies anomalies before they become costly shutdown events.

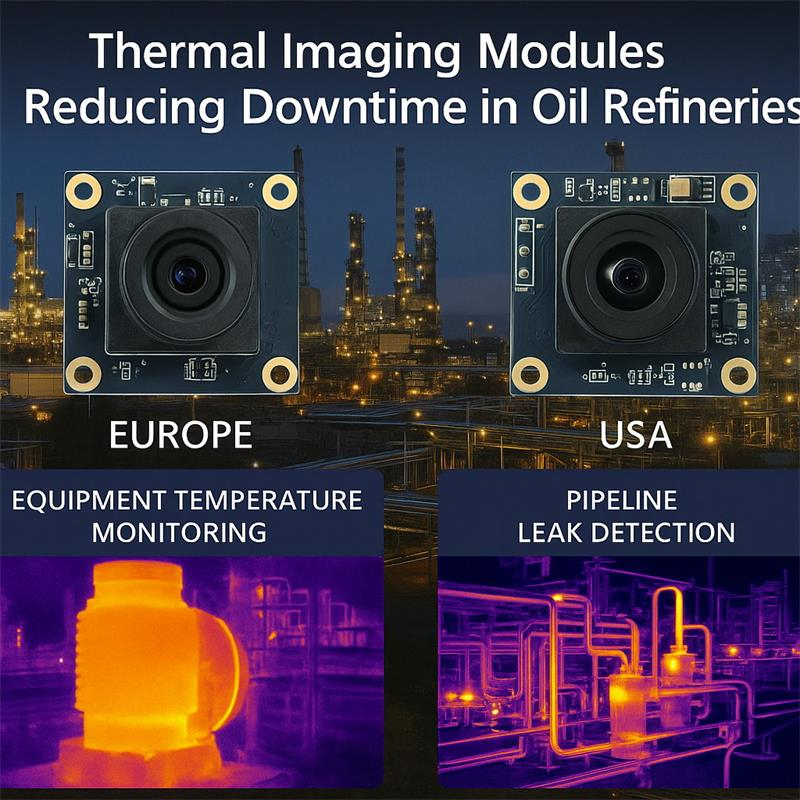

A mid-sized refinery in Texas, processing over 200,000 barrels per day, was experiencing unexpected shutdowns due to overheating in compressor bearings and heat exchangers. Each incident caused up to $1.2M in losses for every 24 hours of downtime.

Our 384-resolution micro thermal imaging camera modules were integrated into the refinery’s predictive maintenance system. These compact modules were embedded into existing machine vision enclosures near rotating equipment and pipelines.

Key results:

The refinery reduced unplanned downtime incidents by 38% within the first year. ROI was achieved in less than 6 months, with savings exceeding $6M annually.

A large refinery in Rotterdam faced challenges in monitoring pipeline integrity across kilometers of infrastructure. Traditional inspection teams relied on manual IR spot checks, which often missed small leaks and early-stage corrosion. Environmental regulators were also tightening compliance requirements for leak detection and repair (LDAR).

The refinery adopted our 640-resolution micro thermal imaging modules integrated with drones and fixed monitoring stations.

Applications included:

Our thermal imaging solutions deliver advantages that directly align with refinery needs:

For refinery CEOs and CTOs, the deployment of thermal imaging modules isn’t just a cost-saving measure—it is a strategic enabler:

Q1: Which resolution (256, 384, 640) is best for refinery applications?

A1: For close-up equipment monitoring, 256 is sufficient. For pipeline monitoring or integration with drones, 384 or 640 ensures higher accuracy.

Q2: Can thermal modules integrate with existing SCADA or AI systems?

A2: Yes. Our modules offer USB, CVBS, and IP-compatible outputs that connect seamlessly with SCADA and edge-AI platforms such as NVIDIA Jetson.

Q3: How durable are these modules in harsh environments?

A3: Modules are IP-rated, tested for vibration, and built for 24/7 operation in high-temperature and high-dust refinery conditions.

Q4: What ROI can industrial clients expect?

A4: Based on deployments, most refineries report ROI within 6–12 months, primarily due to avoided shutdowns and reduced maintenance costs.

Thermal imaging isn’t a “nice-to-have” technology—it’s becoming a mission-critical tool for oil & gas companies in the U.S. and Europe. With micro thermal imaging camera modules (256, 384, 640), refineries can move from reactive maintenance to predictive and preventive operations, significantly cutting downtime costs while enhancing safety and compliance.

For refinery leaders focused on operational excellence, the question is no longer if thermal imaging should be deployed—it’s how quickly it can be scaled across all critical assets.