Thermal Imaging Module Comparison: Resolution, Size, and Interface Options for North America and Europe

Introduction

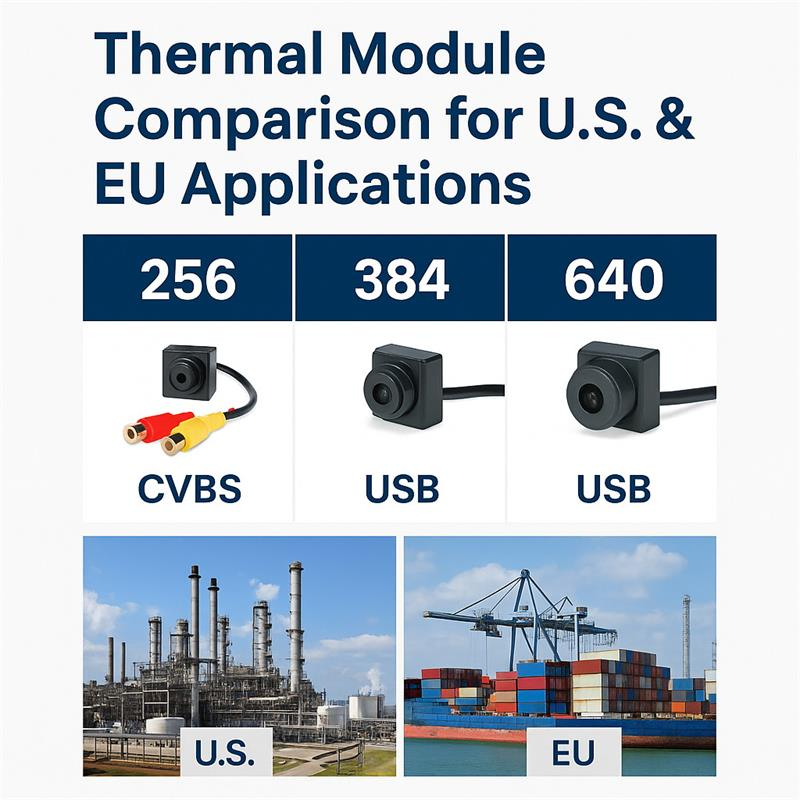

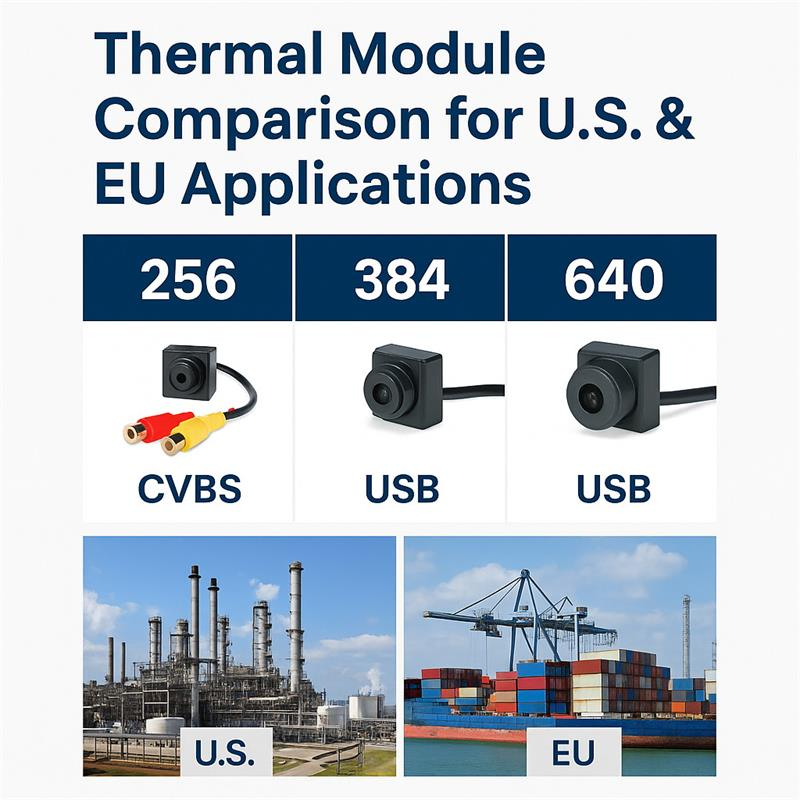

Selecting the right thermal imaging module for your application requires a clear understanding of resolution, module size, and interface options, each impacting performance and suitability across industries like industrial monitoring, consumer electronics, robotics, and hunting. At Shenzhen Novel Electronics Limited, our micro thermal imaging modules (resolutions: 256x192, 384x288, 640x512, 1280x1024; sizes: 21x21mm, 25x25mm, 28x28mm; interfaces: USB2.0, USB-C, CVBS) offer versatile solutions tailored to diverse needs. This blog compares these specifications, highlighting their performance advantages, differences, and ideal use cases for engineers and product managers in North America and Europe.

Resolution Comparison: 256x192, 384x288, 640x512, 1280x1024

1. 256x192

- Performance Advantages: Cost-effective with sufficient thermal sensitivity (<50mK NETD) for basic applications. Low power consumption (~0.35W) extends battery life in portable devices. Ideal for budget-conscious projects requiring basic thermal detection.

- Differences: Lower resolution limits detail in complex scenes, making it less suitable for high-precision tasks. Offers a good balance for wide-area monitoring with a 4mm lens (wide FOV).

- Applications: Consumer electronics (e.g., smartphone thermal accessories in Toronto), hunting scopes in Helsinki, and basic HVAC inspections in Mexico City. Best for cost-sensitive applications where fine detail is less critical.

- Use Case: A Toronto startup uses the 256x192 USB thermal camera for a DIY home inspection tool, detecting heat leaks with minimal cost.

2. 384x288

- Performance Advantages: Balances cost and performance with improved detail over 256x192. Suitable for mid-range applications requiring moderate resolution and high sensitivity. Supports both 4mm (wide FOV) and 9.7mm (focused) lenses.

- Differences: Offers clearer images than 256x192 but less detail than 640x512. Moderate power consumption (~0.5W) suits semi-portable devices.

- Applications: Industrial predictive maintenance (e.g., furnace monitoring in Pittsburgh), robotics navigation in Monterrey, and SAR drones in Calgary. Ideal for applications needing reliable imaging without premium costs.

- Use Case: A Pittsburgh steel plant uses the 384x288 USB thermal camera for robotic furnace inspections, reducing downtime by 15%.

3. 640x512

- Performance Advantages: High resolution provides detailed thermal imaging for critical applications. Excellent for long-range detection (up to 500m with a 9.7mm lens) and precise diagnostics. High sensitivity ensures clarity in low-contrast environments.

- Differences: Higher cost and power consumption (~0.7W) than 384x288. Requires more processing power for real-time analysis, making it less ideal for low-budget projects.

- Applications: High-end industrial inspections (e.g., PCB analysis in Munich), military drones in Warsaw, and energy security (e.g., pipeline monitoring in Houston). Best for applications demanding superior image quality.

- Use Case: A Munich automotive supplier uses the 640x512 USB thermal camera for PCB inspections, improving defect detection by 18%.

4. 1280x1024

- Performance Advantages: Ultra-high resolution delivers exceptional detail for mission-critical applications. Ideal for long-distance surveillance and complex thermal analysis. Supports advanced AI vision with thermal camera for precise object detection.

- Differences: Highest cost and power consumption (~1W), requiring robust processing systems. Less common in consumer applications due to price.

- Applications: Military surveillance (e.g., border monitoring in Texas), advanced industrial diagnostics in Stuttgart, and medical imaging in Barcelona. Suited for high-stakes, high-budget projects.

- Use Case: A Texas defense contractor uses the 1280x1024 USB thermal camera for border surveillance drones, achieving 30% better detection accuracy.

Resolution Selection Guide: Choose 256x192 for cost-sensitive consumer or hunting applications, 384x288 for mid-range industrial and robotics tasks, 640x512 for high-detail industrial and military needs, and 1280x1024 for premium, mission-critical applications.

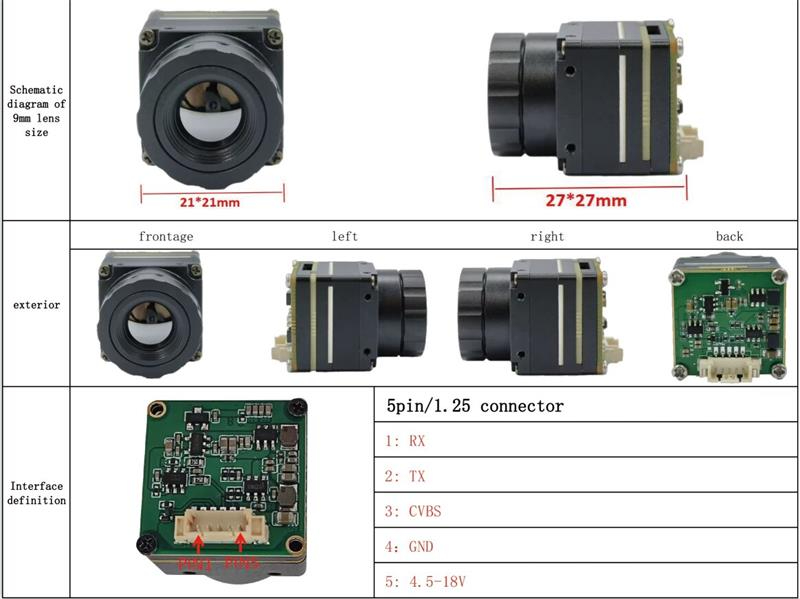

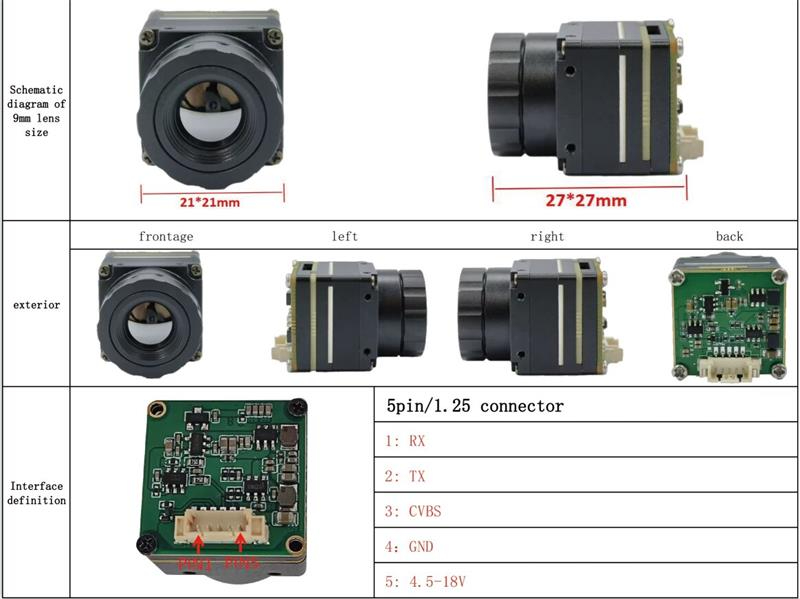

Module Size Comparison: 21x21mm, 25x25mm, 28x28mm

1. 21x21mm

- Advantages: Ultra-compact, weighing ~20g, ideal for drones, wearables, and space-constrained robotics. Minimizes payload and power draw, enhancing portability.

- Applications: Consumer electronics (e.g., smartphone accessories in California), drone-based SAR in Calgary, and hunting scopes in Helsinki. Best for applications prioritizing SWaP (size, weight, power).

- Use Case: A Calgary SAR drone uses the 21x21mm USB thermal sensor to reduce payload, extending flight time by 8 minutes.

2. 25x25mm

- Advantages: Balances compactness and thermal performance. Slightly larger for better heat dissipation, suitable for continuous operation in industrial settings. Weighs ~22g.

- Applications: Industrial monitoring (e.g., factory inspections in Pittsburgh), robotics in Monterrey, and consumer tools in London. Ideal for semi-permanent installations.

- Use Case: A Monterrey agricultural drone uses the 25x25mm infrared camera module for crop monitoring, balancing size and durability.

3. 28x28mm

- Advantages: Larger size (~25g) supports enhanced thermal stability and lens compatibility for high-resolution modules (e.g., 1280x1024). Suited for fixed installations requiring robust performance.

- Applications: High-end industrial diagnostics in Munich, energy security in Houston, and military surveillance in Warsaw. Best for applications where size is less critical than performance.

- Use Case: A Munich PCB inspection system uses the 28x28mm thermal camera with USB-C for stable, high-resolution imaging.

Size Selection Guide: Select 21x21mm for drones and wearables, 25x25mm for balanced industrial and robotics applications, and 28x28mm for high-performance, fixed installations.

Interface Comparison: USB2.0, USB-C, CVBS

1. USB2.0

- Advantages: Universal compatibility with older systems (e.g., PCs, Raspberry Pi). Data transfer rate (~480Mbps) supports real-time imaging for 256x192 and 384x288 resolutions. Cost-effective for embedded systems.

- Disadvantages: Slower than USB-C, less suitable for high-resolution (1280x1024) real-time streaming.

- Applications: Industrial monitoring (Pittsburgh), robotics (Monterrey), and consumer tools (Toronto). Ideal for legacy systems and cost-sensitive projects.

- Use Case: A Pittsburgh factory uses the USB2.0 thermal camera for embedded systems to monitor furnaces via a Raspberry Pi.

2. USB-C

- Advantages: Faster data transfer (~5Gbps) supports high-resolution imaging (640x512, 1280x1024). Modern compatibility with smartphones, tablets, and industrial PCs. Supports power delivery, reducing cabling.

- Disadvantages: Higher cost than USB2.0, less common in older systems.

- Applications: Consumer electronics (California), SAR drones (Calgary), and high-end industrial diagnostics (Stuttgart). Best for modern, high-bandwidth applications.

- Use Case: A California startup uses the thermal camera with USB-C for a smartphone thermal accessory, enabling fast data transfer.

3. CVBS

- Advantages: Analog output ensures compatibility with legacy DVRs and monitors, common in security and industrial setups. Simple, low-cost integration for basic applications.

- Disadvantages: Limited to analog resolution (~720x576), unsuitable for high-resolution modules or digital processing.

- Applications: Energy security (Houston), industrial monitoring (Rotterdam), and basic surveillance (Mexico City). Ideal for legacy analog systems.

- Use Case: A Houston refinery uses the CVBS thermal camera module for pipeline monitoring with existing analog displays.

Interface Selection Guide: Choose USB2.0 for cost-effective, legacy-compatible applications, USB-C for modern, high-resolution systems, and CVBS for analog-based industrial or security setups.

Conclusion and Call to Action

Shenzhen Novel Electronics Limited’s micro thermal imaging modules offer tailored solutions for North America and Europe. The 256x192 USB thermal camera suits consumer and hunting applications, while the 384x288 USB thermal camera and 640x512 USB thermal sensor excel in industrial and robotics tasks. The 1280x1024 infrared camera module is ideal for mission-critical applications. Module sizes (21x21mm, 25x25mm, 28x28mm) and interfaces (USB2.0, USB-C, CVBS) provide flexibility for diverse needs. Contact us at office@okgoobuy.com or +86 755 29775656 to request a demo, download our datasheet, or discuss OEM solutions. Visit our website to select the perfect thermal sensor for robotics navigation or USB thermal camera for predictive maintenance for your 2025 projects!