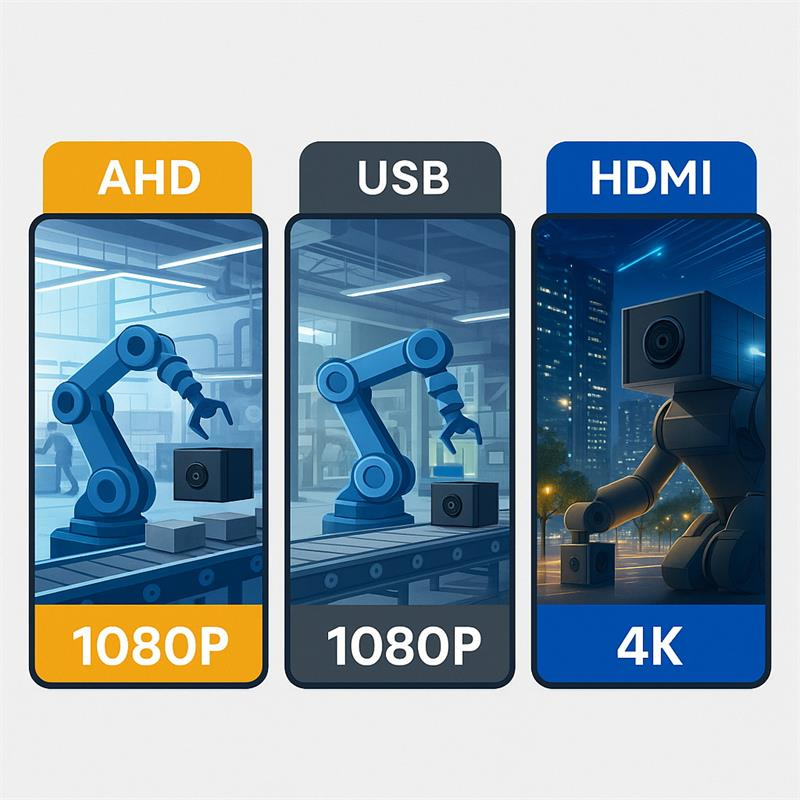

In today’s manufacturing and industrial monitoring markets, especially in the U.S. and Europe, selecting the right camera sensor resolution and interface type can determine whether your vision system achieves operational efficiency or suffers from bottlenecks.

From precision robotic assembly to large-area industrial surveillance, camera specifications must match the exact demands of the application — not just in resolution but also in interface compatibility, latency, and integration complexity.

This guide will walk you through how to select between different sensor resolutions and interfaces, using real-world examples and referencing proven products such as:

We’ll also highlight five actual U.S. and European industrial equipment & monitoring cases to illustrate practical decision-making.

Choosing the correct resolution is about balancing detail, processing speed, and cost.

Perfect for space-constrained embedded systems. For example:

Ideal for retrofit upgrades in existing analog-based monitoring systems, particularly where long-distance transmission and low interference are priorities.

The ultra-compact footprint makes it perfect for tight enclosures, such as industrial machine housings or portable inspection borescopes.

Engineered for operator-based inspection where visual clarity is paramount, such as industrial inspection kiosks or medical/lab imaging.

A packaging facility in Ohio integrated 15×15 mm USB 5 MP cameras to check label alignment and barcode readability on high-speed conveyors. The USB interface enabled direct connection to a Linux-based control PC running OpenCV, ensuring detection accuracy over 98% without slowing throughput.

Key takeaway: 5 MP offers enough detail for small print recognition without overloading system resources.

A Stuttgart-based automotive supplier adopted IMX678 HDMI 8 MP cameras for manual inspection of precision gear components. Operators could instantly view real-time video on 27” 4K monitors, allowing micro-surface defects to be spotted before shipment.

Key takeaway: HDMI output ensures zero-latency visual feedback, critical in manual quality control.

A food plant in Birmingham implemented 15×15 mm AHD 2 MP cameras with 50 m cable runs to monitor stainless-steel mixing tanks. AHD technology provided EMI-resistant video transmission in an environment with strong motor interference.

Key takeaway: AHD is optimal for electrically noisy industrial spaces requiring long cable runs.

An offshore wind farm control room used 6×6 mm AHD 1 MP cameras inside sealed housings to monitor hydraulic actuator positions. Compact size allowed placement within weatherproof enclosures while maintaining wide field-of-view coverage.

Key takeaway: Ultra-miniature analog cameras excel in harsh, space-restricted environments.

A Silicon Valley electronics manufacturer equipped its Cobots with Novel 15×15 mm USB camera 2 MP for vision-guided PCB testing. Plug-and-play USB integration meant each robot could be re-tasked for different products within hours.

Key takeaway: Low-weight, compact USB modules help maintain Cobot arm precision while enabling quick redeployment.

|

Application |

Resolution |

Interface |

Recommended Product |

|

High-speed object presence detection |

1–2 MP |

AHD |

6×6 mm AHD Camera |

|

Barcode/label verification |

5 MP |

USB |

15×15 mm USB 5 MP |

|

Large-area defect inspection |

8–12 MP |

USB / HDMI |

IMX678 HDMI 8 MP / USB 12 MP |

|

Long-distance harsh environment monitoring |

1–2 MP |

AHD |

15×15 mm AHD 2 MP |

|

Precision robotic grasping |

2–5 MP |

USB |

15×15 mm USB 2/5 MP |

Selecting the right sensor resolution and interface type is not a one-size-fits-all decision. Factors such as field of view, required detail level, processing capabilities, cable distance, and environmental conditions all influence the choice.

From the Novel 15×15 mm USB camera series to ultra-compact 6×6 mm AHD modules and the IMX678 HDMI camera, there is a solution to fit every industrial application — whether you’re running a Cobot in a Silicon Valley lab, an automotive inspection station in Germany, or a food processing line in the UK.

Shenzhen Novel Electronics Limited delivers customizable embedded vision systems for industrial, robotics, and monitoring applications across the U.S. and Europe. Contact us to discuss how our compact, high-performance camera modules can optimize your next vision project.