Micro camera modules have become essential components in robotics and industrial automation, enabling precise visual feedback for tasks such as inspection, navigation, quality control, and machine vision. However, selecting the right camera module requires careful consideration of several factors to ensure seamless integration and optimal system performance.

This article outlines the key considerations when choosing micro camera modules for robotics and industrial automation applications, helping engineers and system integrators make informed decisions.

Robotics and automated equipment often impose strict space constraints. Compact modules like Shenzhen Novel Electronics’ 15×15mm micro usb cameras (model Number: UC-501) are ideal, enabling installation in tight spaces such as robotic end-effectors, embedded inspection tools, or compact control panels.

Choosing a module with the smallest possible footprint without sacrificing performance is critical for unobtrusive integration.

The required image resolution depends on the application:

Ensure the camera supports stable frame rates for smooth video processing and machine learning inference.

Selecting the right interface simplifies integration:

Robots and automation systems may operate under varied lighting. Cameras with high sensitivity sensors (e.g., 0.001Lux or better) and optional IR support help maintain image quality in dim or no-light conditions.

Industrial environments may expose cameras to dust, moisture, vibration, and temperature extremes. Look for:

Shenzhen Novel Electronics offers ruggedized camera modules tailored for harsh conditions.

Lower power draw extends battery life in mobile robots and reduces thermal impact in compact systems. USB-powered modules simplify wiring but verify total power requirements.

Availability of SDKs, sample code, and compatibility with popular vision frameworks like OpenCV accelerate development. Shenzhen Novel Electronics provides comprehensive integration support.

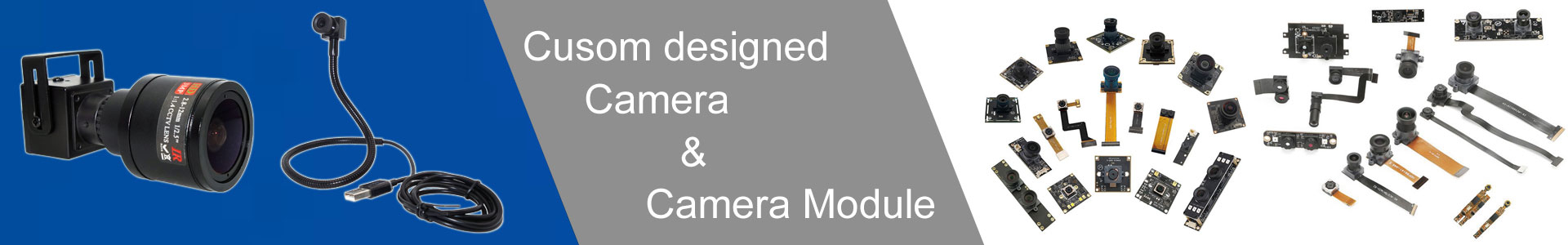

Choosing the right micro camera module involves balancing size, resolution, interface, environmental resistance, and software support. Shenzhen Novel Electronics’ diverse portfolio of micro USB, AHD, and CVBS cameras provides flexible options tailored for robotics and industrial automation needs.

Looking for reliable micro camera modules?

Contact Shenzhen Novel Electronics for expert advice, samples, and custom solutions.

office@okgoobuy.com

UC-501 usb camera www.okgoobuy.com/2mp-mini-usb-camera.html