4K IMX678 STARVIS 2 USB module gives robots and industrial AI vision systems detailed imaging for defect detection and scene analysis. USB2.0 UVC and compact M12 design simplify embedded integration

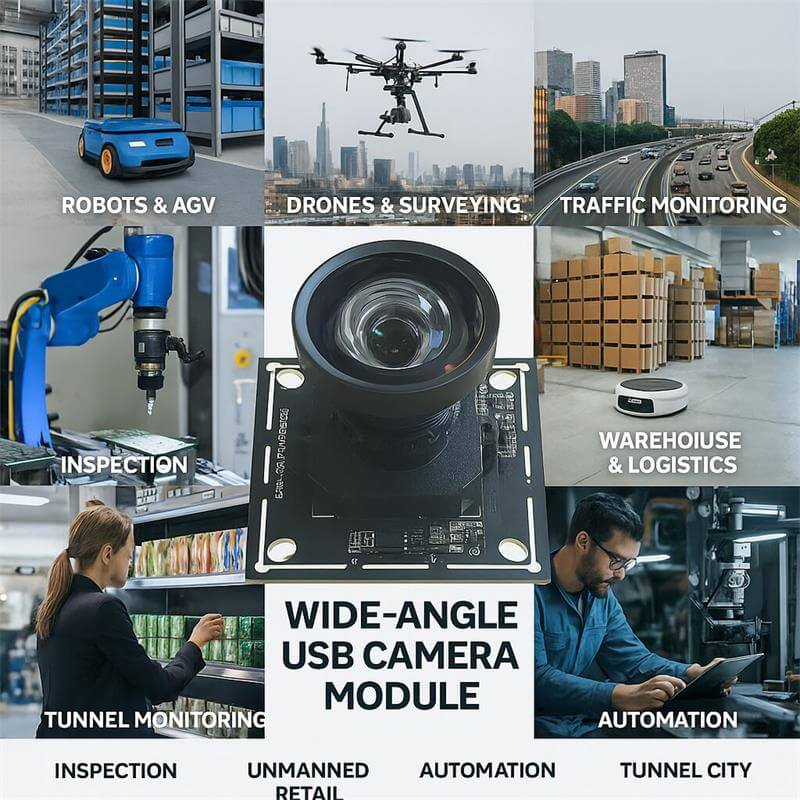

The Goobuy 4K IMX678 USB Camera Module UCM-678-4K integrates Sony’s STARVIS 2 8.29 MP 1/1.8″ sensor, delivering true 4K resolution, HDR performance and plug-and-play USB 2.0 UVC interface. Built for machine vision, robotics, automation and embedded devices, the ultra-compact board enables rapid deployment in inspection systems, SLAM robots, kiosks and AI edge platforms

Product Overview

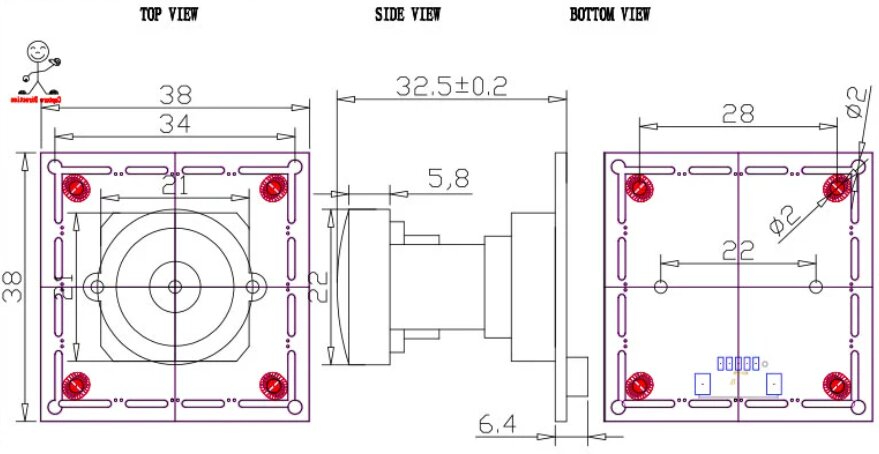

The IMX678 STARVIS 2 USB Camera Module Goobuy UCM-678-4K is designed for advanced embedded vision systems requiring 4K Ultra HD imaging, excellent low-light sensitivity, and wide dynamic range. Built on Sony’s STARVIS 2 1/1.8” CMOS sensor (2.0 µm pixel), it delivers superior starlight performance while keeping bandwidth optimized with UVC-compliant USB output.

With a 38×38 mm PCB and M12 lens mount, the module integrates easily into drones, robots, and industrial monitoring devices. It is ideal for real-time 4K video streaming, machine vision applications, and 24/7 surveillance of energy facilities.

✔ Ultra-compact + 4K resolution: Power meets miniaturization.

✔ Unmatched low-light imaging with Sony STARVIS 2 technology.

✔ Flexible customization: lens, FOV, interface, cable length.

✔ Industrial-grade reliability: tested for continuous 24/7 operation.

✔ Seamless integration with robotics, smart devices, and industrial PCs.

• Sony STARVIS 2 8.29 MP sensor capturing 3840×2160 at 30fps with exceptional image clarity

• Dual-exposure HDR captures wide dynamic range without motion artifacts

• USB 2.0 UVC interface – driver-free compatibility with Windows, Linux, NVIDIA Jetson and Raspberry Pi

• Ultra-compact board design for embedded integration and space-constrained systems

• M12 lens mount with multiple field-of-view options and low-distortion calibration support

• Ideal for robotics navigation, quality inspection, kiosks, telepresence and smart automation

• Full OEM/ODM customization support (lens, cable length, connector, housing, firmware)

"Upgrade Path: Why Switch to IMX678?"

|

Feature |

IMX415 (Old 4K) |

Goobuy IMX678 (New 4K) |

Benefit for Edge AI |

|

Tech Gen |

STARVIS 1 |

STARVIS 2 |

Better Low Light |

|

Pixel Size |

1.45μm (Small) |

2.0μm (Large) |

Higher SNR / Less Noise |

|

HDR |

DOL-HDR (Ghosting) |

SE-HDR (No Ghosting) |

Clear Moving Objects |

|

Sensor Size |

1/2.8" |

1/1.8" (Big) |

More Light Intake |

Transparency is key to a successful engineering partnership. Here are the detailed specifications for our standard module.

|

Category |

Specification |

|

Sensor |

Sony starvis 2 IMX678 (1/1.8") |

|

Max. Resolution |

3840(H) x 2160(V) @30fps |

|

Interface |

USB 2.0 High Speed |

|

Output Format |

MJPEG / YUV2 (YUYV) |

|

Frame Rate (MJPEG) |

3840x2160 @ 30fps, 1920x1080 @ 60fps, 1280x720 @ 60fps |

|

Frame Rate (YUV) |

3840x2160 @ 1fps, 1920x1080 @ 5fps, 640x480 @ 30fps |

|

Min. Illumination |

0.5 Lux |

|

Dynamic Range |

72dB |

|

Signal-to-Noise Ratio |

30dB |

|

Focus |

Fixed |

|

Lens |

F2.0 Aperture / 3.05mm Focal Length / 118° D-FOV |

|

OS Support |

Windows, Linux, macOS, Android (UVC Compliant) |

|

Adjustable Controls |

Brightness, Contrast, Saturation, Sharpness, White Balance, Exposure, etc. |

Integration & Compatibility

What problems goobuy imx678 starvis2 usb camera UCM-678-4K can settle for you well?

This camera module is engineered to be a versatile problem-solver, specifically for industrial and commercial applications where deploying high-resolution imaging has traditionally been limited by cost, system compatibility, or environmental challenges.

Here are the key problems it solves and the demands it meets:

1. Problem: Missed Details in Quality Control & Documentation

Lower-resolution cameras (like 1080p) fail to capture microscopic defects, fine print, or critical component details, leading to inaccurate inspections and poor-quality records.

2. Demand: A Cost-Effective Upgrade Path for Legacy Systems

Many factories, labs, and commercial facilities run on industrial PCs and embedded systems that only have USB 2.0 ports. Upgrading this host hardware is expensive and often requires a complete system re-validation.

3. Problem: A "One-Size-Fits-All" Lens Limits Applications

A fixed, built-in lens means a camera is only useful for one specific distance and field of view. Different tasks often require purchasing entirely different cameras.

4. Demand: Reliable Imaging in Challenging, Uncontrolled Lighting

Industrial and commercial environments rarely have perfect lighting. Glare from windows, deep shadows under machinery, and sudden changes in brightness can render standard cameras useless.

5. Problem: Slow Development Cycles Due to Complex Software Integration

Proprietary drivers and complex software development kits (SDKs) can delay projects by weeks or months, creating a significant drain on engineering resources.

This camera module's core strength is its ability to deliver exceptionally detailed 4K resolution over the ubiquitous USB 2.0 interface. The addition of an interchangeable M12 lens mount radically expands its versatility, allowing the Field of View (FOV) to be tailored for specific tasks. It is the ideal choice for applications where image detail, optical flexibility, and broad system compatibility are prioritized over uncompressed, high-speed data transfer.

This module is perfectly suited for static or semi-static inspection tasks where fine detail is critical.

Visual Quality Inspection: The 4K resolution allows for detailed automated or manual inspection of components, PCBs, textiles, and finished goods. It can detect microscopic defects, scratches, or printing errors that lower-resolution cameras would miss.

Process Monitoring: Monitor a specific station on an assembly line. With a telephoto M12 lens, it can focus on a critical component from a safe distance. With a wide-angle lens, it can oversee the entire work area.

Meter & Gauge Reading: The high resolution enables Optical Character Recognition (OCR) or manual reading of analog gauges, digital displays, and meters from across a room.

The module's high resolution makes it an excellent engine for a variety of digital capture systems.

High-Resolution Document & ID Scanning: Integrate into kiosks or desktop systems to capture crystal-clear images of documents, passports, and ID cards for archiving or verification. The 4K detail ensures that all text and security features are perfectly legible.

Digital Microscopy: A highly cost-effective method to upgrade traditional analog microscopes to 4K digital imaging systems. The interchangeable M12 mount allows for direct coupling to microscope eyepieces or C-mount adapters.

Scientific & Lab Imaging: For applications like sample monitoring, gel electrophoresis documentation, or general lab observation where high-resolution still images or compressed video are sufficient.

While not a high-speed machine vision camera, its sensor and resolution provide significant advantages in security and monitoring.

High-Clarity Surveillance: Monitor wide areas like lobbies, warehouses, or retail floors. The 4K resolution allows for effective digital zoom during playback to identify faces, objects, or incidents with much greater detail than 1080p cameras.

Kiosks, ATMs & Vending Machines: The simple plug-and-play UVC over USB 2.0 ensures easy integration. The underlying IMX678 sensor provides reliable performance even with challenging backlighting (e.g., a user standing in front of a bright doorway).

Biometric Systems: Use for facial recognition or iris scanning at access points. The high resolution captures the intricate details needed for accurate biometric algorithms. The sensor's strong NIR potential can be leveraged for systems using infrared illumination.

The combination of a powerful sensor, standard interface, and optical flexibility makes this an ideal building block for new product development.

Medical Device Imaging (Non-Diagnostic): Can be integrated into dental cameras, skin analyzers, or telemedicine systems where high-resolution visual documentation is required.

Agricultural Technology (AgriTech): Monitor plant health, germination, or pests in controlled environments. The ability to use a macro M12 lens allows for detailed close-up views.

Client-Facing Systems: Integrate into high-end video conferencing bars, interactive displays, or product demonstration tools where superior image quality is a key feature.

Integration & Platform Compatibility

Operating Systems

• Windows 10/11

• Ubuntu 18.04–22.04

• NVIDIA Jetson OS

• Raspberry Pi OS

• Android (UVC)

Frameworks

• ROS2 (Foxy, Humble)

• OpenCV 4.x

• GStreamer

• TensorFlow Lite

• PyTorch / ONNX Runtime

Hardware Platforms

• NVIDIA Jetson Orin / Xavier NX / Nano

• Raspberry Pi 5 / 4

• x86 Embedded PC

• ARM industrial boards

Customer story/case study

A U.S. robotics integrator deployed the IMX678 module in an autonomous warehouse robot fleet. By leveraging its 4K imaging and low-lux sensitivity, they achieved 40% improvement in navigation accuracy during night shifts while keeping CPU usage low thanks to MJPEG compression.

FAQ for Engineers & Integrators

Q1. What advantages does the Goobuy UCM-678-4K have over lower-resolution USB cameras?

A1. The 8.29 MP 4K resolution provides ultra-fine detail, enabling accurate text, label and defect recognition, while the STARVIS performance ensures strong low-light capability.

Q2. Is the USB2.0 interface sufficient for 4K performance?

A2. Yes — the camera outputs compressed UVC MJPG/YUY2 stream optimized for 4K@30fps USB 2.0. It is optimized for embedded systems and requires no USB3.0 bandwidth.

Q3. Can Goobuy UCM-678-4K USB Camera module be integrated easily into a robotics SLAM or VIO pipeline?

A3. Absolutely. It supports M12 lens mount and comes with calibration data (intrinsics/distortion) and is ROS2 compatible, making integration with SLAM frameworks streamlined.

Q4. What customization options are available for OEM integration?

A4. Shenzhen Novel Electronics limited supports customized lens/focal length, lens mount type, cable/connector configuration, housing modifications, firmware tuning and full integration support for this starvis2 imx678 UCM-678-4K camera .

Q5. What environments is this IMX678 USB module Goobuy UCM-678-4K suited for?

A5. It is designed for embedded and industrial deployment, including factory automation, inspection systems, robotics in warehouse/field, kiosks, telepresence, and smart city applications.

Q6: "Is the 1/1.8" sensor compatible with standard M12 lenses?"

A6: The 1/1.8" format is larger than standard 1/2.7" or 1/3" sensors. You must use large-format M12 lenses to avoid vignetting (dark corners). Goobuy ships this module with a matched 1/1.8" wide-angle lens by default.

Q7: "What is the power consumption of Goobuy Imx678 USB Camera module UCM-678-4K?"

A7: The IMX678 is a high-performance sensor. Our module typically draws 200mA-300mA @ 5V. Ensure your Edge AI box's USB port can supply stable current, especially when using long cables.

GStreamer (Linux)

Bash

# Example: GStreamer pipeline to test 4K stream on Linux/Jetson

gst-launch-1.0 v4l2src device=/dev/video0 ! \

image/jpeg, width=3840, height=2160, framerate=30/1 ! \

jpegdec ! videoconvert ! xvimagesink

Relative technical Articles and application links

1, Goobuy — Professional Micro USB Camera for AI Edge Vision

2, Choosing 2025 Best USB Camera for Edge AI Retail Systems

3, 14*14mm 4K Micro USB Camera for AI Edge vision

4, Choosing the Right USB Camera for Edge AI in 2026

5, Sony IMX678 Starvis 2 HDMI Camera Module Guide

6, STARVIS 2 vs STARVIS 1 – Low-Light & NIR Advancements