Why Are Autofocus Mini USB Camera Modules So Important for Robotic Vision?

Autofocus mini USB camera modules hold a central position in robotic vision. Their importance stems from the core requirement of robotic vision — accurately perceiving the environment to enable autonomous decision-making and operation — and these modules are specifically designed to address key challenges robots face during perception. Below is a detailed analysis from multiple dimensions:

1. Autofocus: Ensuring Image Clarity in Dynamic Scenes — The Foundation of Accurate Robotic Perception

During operation, a robot’s distance from its target often changes dynamically (e.g., approaching/receding from objects, handling items at varying distances). Clear imaging is the foundation for effective visual algorithms such as object detection, feature extraction, and positioning.

- Dynamic Distance Adaptation

For example, in industrial robotics, parts moving along a conveyor belt constantly change their distance to the camera; in service robots, user interaction involves the user moving closer or farther away. Autofocus can use built-in distance sensors (e.g., laser, ultrasonic) or contrast-based image analysis to adjust the focal length in real time, ensuring sharp images at any distance.

- Reliability in Detail Recognition

Details such as surface textures on components, QR codes, or user gesture paths depend on image clarity. With fixed-focus lenses, targets too near or far become blurry, causing algorithm errors (e.g., misidentifying parts, failing to read codes). Autofocus eliminates these problems by keeping details sharp.

2. Miniaturization: Meeting Space and Weight Constraints in Robotics

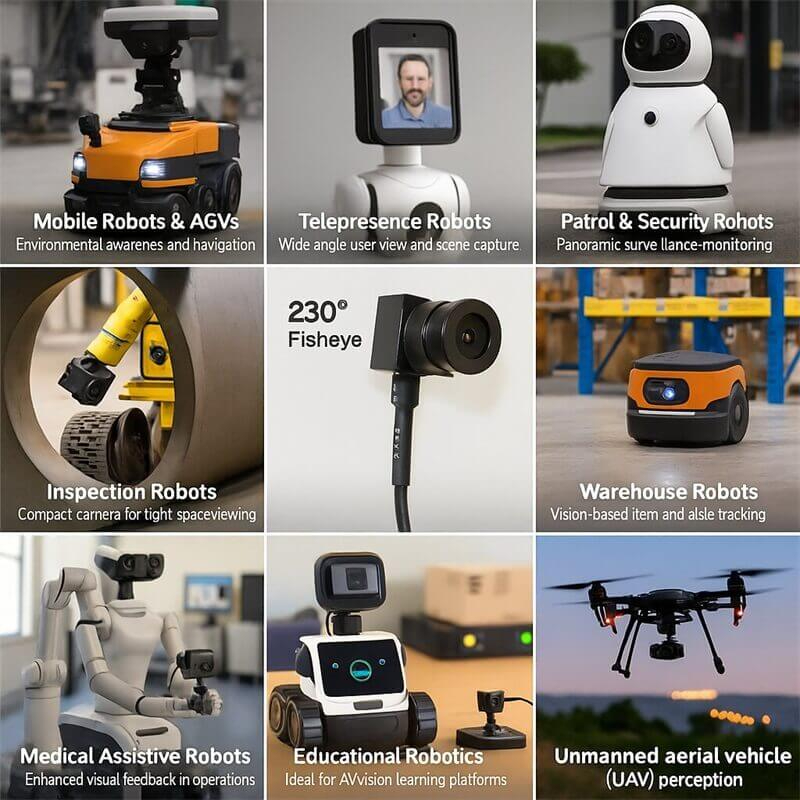

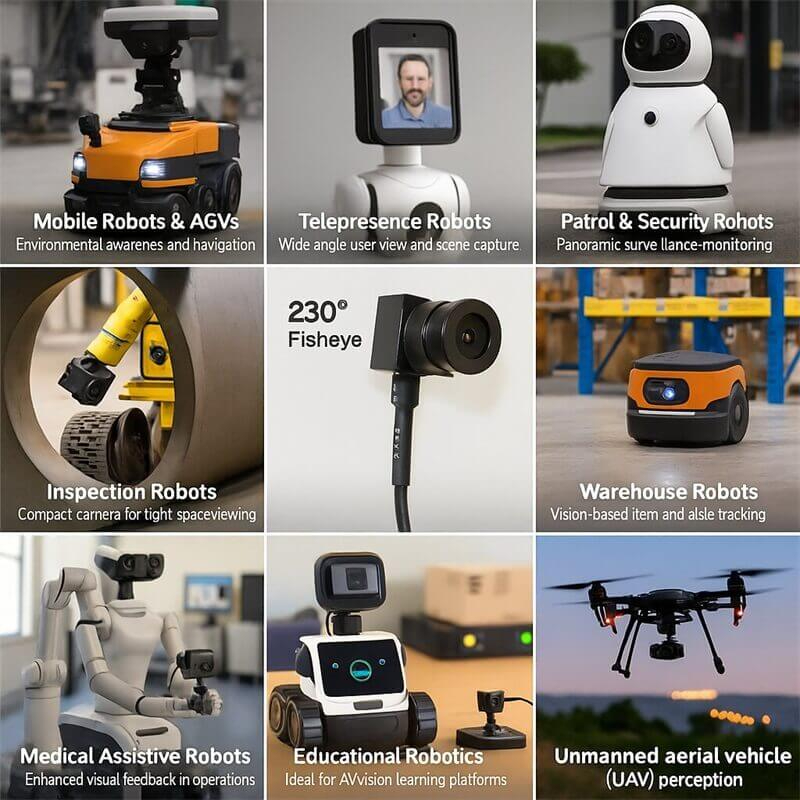

Robots — especially small collaborative robots, AGVs, drones, and service robots — face strict volume and weight limits. Mini camera modules are a must-have for integrating vision systems.

- Space Compatibility

Robotic arms, heads, and chassis often have very limited space. Mini modules, often just a few centimeters or millimeters in size, can be embedded without restricting movement range (e.g., arm rotation) or mobility in narrow environments.

- Lightweight Advantage

Smaller modules weigh less, reducing inertia in moving robots (such as fast-moving AGVs or drones), improving control accuracy, and avoiding vibration or balance issues caused by heavy components.

- Deployment Flexibility

Their compact size allows placement in multiple locations on the robot (head, arms, chassis perimeter) to provide diverse perspectives and improve environmental awareness.

3. USB Interface: Plug-and-Play and Standardization

- Ease of Integration

USB (especially USB 2.0/3.0) is a mature and widely adopted interface standard, eliminating the need for complex custom video capture circuitry. This reduces development complexity and cost.

- Simple Connection & Expansion

Cameras connect directly to a robot’s main controller (e.g., Raspberry Pi, Jetson Nano, industrial PC) via standard USB ports, with straightforward wiring. Multiple cameras can be added via USB hubs.

- Sufficient Data Throughput

USB 2.0/3.0 provides enough bandwidth to transmit mainstream resolutions (720p, 1080p) in real time, meeting most robotic vision requirements.

- Integrated Power Supply

USB delivers both data and 5V power, removing the need for a separate power line and simplifying system design.

- Cross-Platform Compatibility

Many robotic control systems run Linux or ROS (Robot Operating System). USB cameras integrate easily via standard drivers without complex protocol adaptation (unlike GigE Vision or MIPI).

- Maintainability & Upgradability

Standardized USB modules are easy to replace or upgrade (e.g., from 2MP to 5MP) without altering the robot’s core hardware.

4. Autofocus (Revisited): Adapting to Dynamic Environments

- Overcoming Depth-of-Field Limitations

Fixed-focus lenses either have a shallow depth of field (clear close-up, blurry distant objects) or sacrifice resolution for a large depth of field (small aperture reduces brightness; wide-angle lenses introduce distortion). Autofocus continuously adjusts focus for consistently sharp imaging.

- Enhancing Visual Task Accuracy

Clear images are essential for computer vision algorithms such as object recognition, feature detection, dimension measurement, barcode reading, precision grasping, and SLAM mapping. Blurry images degrade detection accuracy, positioning precision, and overall task success rates.

- Flexibility

Allows robots to handle tasks at varying distances without manual lens changes or adjustments — from identifying distant navigation markers to inspecting small nearby components.

- Ease of Use

Eliminates the need for manual focusing, improving robot autonomy.

5. Camera Module as an Integrated Solution

- All-in-One Design

The module integrates lens, image sensor, autofocus mechanism (e.g., voice coil motor), and necessary circuitry into a compact, stable unit.

- Optimized Lens-Sensor Pairing

Lenses and sensors are matched for optimal optical performance.

- Procurement & Replacement Convenience

Standardized modules are easy to source and replace when damaged.

6. Comprehensive Improvement in Robotic Vision Practicality & Adaptability

The ultimate goal of robotic vision is for robots to autonomously complete tasks in complex environments. Autofocus mini USB camera modules deliver “clear perception + flexible integration + easy adaptation” to achieve this goal:

- In Industrial Settings: Enable precise gripping of parts at varying distances; detect surface defects that require high-detail imaging.

- In Service Settings: Recognize facial expressions at changing distances; read printed menus or documents from different ranges.

- In Navigation: Identify moving obstacles at varying distances; read road signs or markers with clarity.

Conclusion

The importance of autofocus mini USB camera modules lies in how perfectly they meet the core needs of robotic vision:

- Miniaturization – Providing vision capabilities within space-constrained environments.

- USB Interface – Achieving quick, low-cost system integration.

- Autofocus – Capturing clear images in complex, dynamic environments.

- Clear Imaging – Supplying reliable inputs for advanced vision algorithms.

Example Applications

- Service Robots: Face, gesture, and object recognition; indoor navigation at varying distances.

- Logistics AGV/AMR: Reading shelf labels/QR codes at different heights and distances; docking accurately with shelves or charging stations.

- Industrial Robotic Arms: Guiding precision pick-and-place of parts of varying sizes and positions; performing vision-based inspection.

- Drones: Capturing ground targets or avoiding obstacles at changing altitudes.

- Educational/Research Robots: Quickly prototyping and testing vision algorithms.

In summary, autofocus solves the “image quality at variable distances” challenge, miniaturization breaks “space constraints in robotics”, and USB lowers the “integration threshold”. Together, they make these modules the ideal hardware platform for robotic visual perception — directly determining whether a robot can interact with its environment efficiently and accurately.