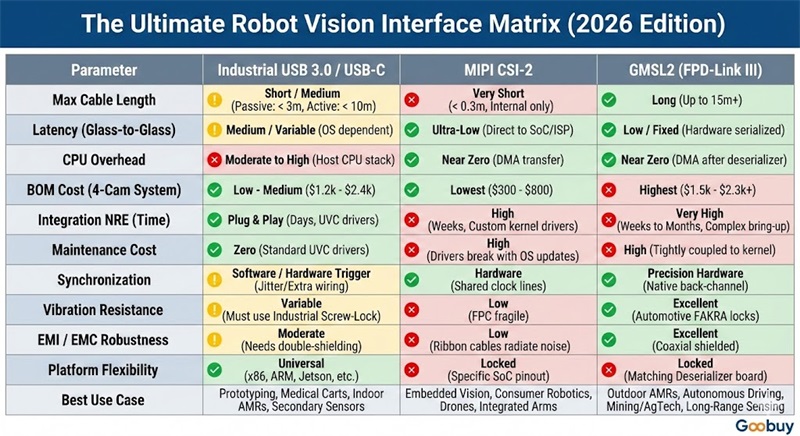

In the 2026 Physical AI landscape, robotic vision architecture is defined by a strategic trade-off: GMSL2 is the mandatory standard for long-range outdoor ruggedness (AgTech, Mining), MIPI CSI-2 dominates compact mass production (Consumer, Medical Arms), and Industrial USB camera is the optimal solution for rapid prototyping and indoor autonomy due to its zero-NRE integration and 60% lower BOM cost.

By Shenzhen Novel Electronics limited Goobuy Team | January 20, 2026

In 2026, the robotics industry has shifted its focus to Physical AI—where embodied agents interact dynamically with the real world. This shift has placed unprecedented pressure on vision systems. Robots now require higher resolution, lower latency, and multi-camera fusion to feed hungry Vision Language Models (VLMs).

However, this creates a hardware paradox. Engineering teams are often forced to choose between three imperfect options:

Choosing the wrong interface is not just a technical glitch; it is a strategic error that can inflate your Total Cost of Ownership (TCO) by 300% or delay your Time-to-Market by months.

This report provides an objective, data-driven framework to evaluate these interfaces based on real-world 2026 industry requirements.

While Bill of Materials (BOM) cost is visible, the "Hidden Costs" of integration and maintenance often determine a product's profitability.

According to developer data from the NVIDIA and ROS ecosystems, the Non-Recurring Engineering (NRE) costs vary significantly between interfaces

An objective breakdown of Year-1 costs for a typical Jetson Orin-based robot.

|

Cost Dimension |

GMSL2 (Automotive Grade) |

MIPI CSI-2 (Embedded) |

Industrial USB 2.0 / 3.0 |

|

Hardware BOM |

High ($1.5k - $2.3k)**Requires Deserializer boards (~$200) & FAKRA cables. |

Lowest ($300 - $800)Inexpensive sensors & FPC cables. Ideal for mass production. |

Medium ($400 - $1.2k)Cost is in the industrial housing & locking cables. |

|

Development NRE |

High ($5k - $15k)Complex driver bring-up, device tree tuning, and SerDes config. |

Medium ($2k - $5k)Requires kernel-level integration; easier if supported by JetPack. |

Zero (Plug & Play)Standard UVC drivers require no kernel development. |

|

Maintenance Risk |

High Drivers often break during JetPack OS upgrades, requiring re-porting. |

Medium Tied to kernel version; requires updates with OS changes. |

Low / Zero UVC standard ensures long-term OS compatibility. |

|

Profit Impact |

Best for high-margin, heavy-duty machinery. |

Best for high-volume, compact consumer devices. |

Best for rapid iteration and mid-range industrial fleets. |

Strategic Insight: CFOs must weigh the recurring maintenance costs of GMSL and MIPI against the upfront slightly higher module cost of Industrial USB.

For startups and R&D teams, speed is the primary currency. The time gap between "hardware arrival" and "first VSLAM demo" is a critical metric.

Industry case studies indicate a stark contrast in prototyping velocity

Strategic Insight: Many successful companies adopt a "PoC-First" strategy: launching prototypes on USB to secure funding/customers quickly, while evaluating GMSL/MIPI for the eventual mass-production version (if necessary).

Engineers often debate "Reliability" vs. "Ease of Use." The truth is that each interface has a "Sweet Spot" based on physics and mechanics.

Comparing the physical capabilities of each interface.

|

Feature |

GMSL2 |

MIPI CSI-2 |

Industrial USB |

|

Cable Reach |

Long (15m+)Coaxial cable; excellent for large robots. |

Very Short (<0.3m)Signal degrades rapidly; internal use only. |

Medium (3-5m)Requires active repeaters for longer runs. |

|

Latency |

Low & Deterministic Hardware serialization; ideal for high-speed control loops. |

Lowest Direct path to ISP; minimum possible latency. |

Variable Subject to OS scheduling (jitter); manageable for navigation. |

|

Vibration |

Excellent Automotive FAKRA connectors are vibration-proof. |

Poor FPC connectors can disconnect or tear under stress. |

Good (with Locks)Industrial Screw-Lock connectors solve the disconnection issue. |

|

Synchronization |

Native Hardware Sync Microsecond precision via back-channel. |

Native Hardware Sync Shared clock lines on PCB. |

Hardware Trigger Possible via external trigger lines, but requires specific Global Shutter sensors. |

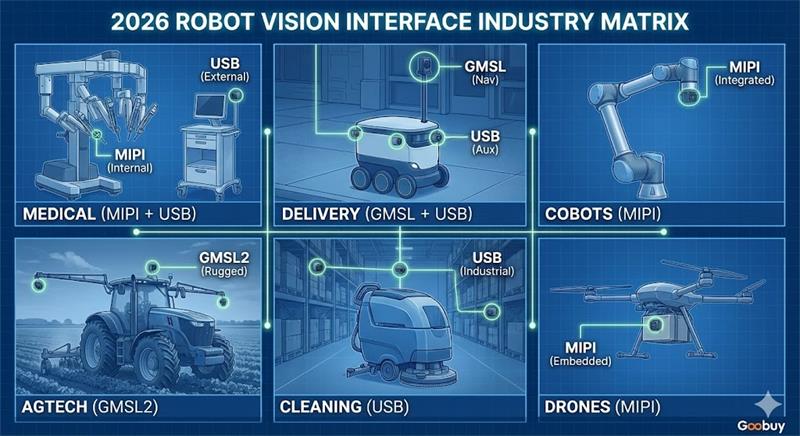

5. Decision Matrix: Selecting the Right Interface for Your Sector

There is no single "best" interface. Based on 2026 deployment data, here are the dominant architectures for specific robot categories.

Medical Carts & Surgical Robots

Dominant Architecture: Internal MIPI + External USB

Why:Surgery (MIPI): Endoscopes require the absolute lowest latency and smallest sensor size (MIPI) to fit inside the arm.

Documentation (USB): External PCs (often x86) lack GMSL inputs. USB is the standard for connecting high-res medical cameras for recording and AI analysis.

Constraint: Sterilization requirements often make thick GMSL coax cables difficult to route.

Last-Mile Delivery Robots (Sidewalk)

Dominant Architecture: Hybrid (GMSL + USB)

Why:Navigation (GMSL): 360° surround view requires long cables (distributed around the chassis) and waterproof (IP67) connectors to survive rain and dust.

Auxiliary (USB): Internal cameras (cargo monitoring) or depth sensors often use USB to reduce the load on the GMSL bandwidth and lower per-unit cost.

Industrial Cobots (Robotic Arms)

Dominant Architecture: MIPI (Integrated) vs. USB (External)

Why:Production Arms: Integrated MIPI sensors reduce weight at the end-effector.

R&D / Flexible Cells: Industrial USB cameras are preferred for external "Eye-to-Hand" setups or rapid prototyping because they can be moved and reconfigured instantly without changing the robot's internal wiring.

Constraint: High-EMI environments (welding) require double-shielded cabling (GMSL or Industrial USB).

Agricultural & Heavy Outdoor AMR

Dominant Architecture: GMSL2

Why:The combination of long cable runs (tractor booms), extreme EMI (diesel engines), and outdoor elements makes GMSL2 (or FPD-Link) the only viable option. USB and MIPI typically cannot survive the mechanical shock or cable length requirements here.

Commercial Cleaning Robots (Indoor)

Dominant Architecture: Industrial USB / MIPI

Why:Cost is the primary driver. For indoor robots moving at low speeds, Automotive GMSL is often considered over-engineering. Industrial USB with screw-locks provides sufficient reliability while keeping the BOM low.

6. The Strategic Roadmap: A Lifecycle Approach to Hardware

Rather than debating "Which is better?", successful robotics companies in 2026 are adopting a Lifecycle Strategy that utilizes different interfaces at different stages of growth.

Based on our market analysis, here is a recommended roadmap for scaling your vision architecture:

Phase 1: The "PoC" Stage (Proof of Concept)

•Objective: Validate algorithms and secure funding immediately.

•Recommended Interface: Industrial USB.

•Strategic Value: By utilizing plug-and-play USB cameras, teams can bypass the "Hardware Trap" of NRE and driver debugging33. This allows you to demonstrate a working Physical AI model in days, not months.

oNote: Ensure you use Global Shutter sensors for valid VSLAM data.

Phase 2: The "Productization" Stage (Scale-Up)

•Objective: Optimize Unit Economics (BOM) and Integration.

•Recommended Interface: Hybrid or MIPI.

•Strategic Value: As volumes increase to 1,000+ units, transitioning primary sensors to MIPI can reduce per-unit costs34. However, keeping secondary sensors (like internal monitoring) on USB or simple connectors often retains architectural flexibility and lowers baseboard complexity.

Phase 3: The "Industrialization" Stage (Mass Deployment)

•Objective: Maximum Reliability in Uncontrolled Environments.

•Recommended Interface: Environment-Dependent.

•Strategic Value:

oFor Outdoor/Harsh deployments, migrating to GMSL2 is a necessary investment for long-term survival35.

oFor Indoor/Controlled deployments, sticking with Industrialized USB (with screw-locks and shielding) often yields the best ROI by avoiding the high maintenance costs of GMSL drivers36.

In 2026, the question is not "Is USB better than GMSL?" but rather "Which interface fits my current product stage and environment?"

At Goobuy, we understand that your needs evolve. From Rapid Prototyping Kits (USB) that get you started in an hour, to Cost-Optimized Modules for your fleet rollout, we provide the impartial expertise and hardware to power your Physical AI journey.

Data Citation Source: Market analysis based on ROS 2 documentation, NVIDIA Developer Forums, and Industrial Robotics industry reports (2025-2026).

Q1: What is the total cost difference between GMSL2 and USB for a 4-camera robot?

A: For a quad-camera setup on NVIDIA Jetson, GMSL2 typically costs 3x to 5x more than Industrial USB. A GMSL2 architecture requires approximately $1,550–$2,300 in hardware (cameras + mandatory deserializer boards + FAKRA cables) plus $5k–$15k in NRE for driver development. In contrast, an Industrial USB architecture costs $400–$1,200 with zero driver development costs due to standard UVC compliance.

Q2: Is USB 3.0 reliable enough for AMRs with high vibration?

A: Yes, provided that Industrial Screw-Lock connectors are used. Consumer USB Type-A plugs rely on friction and will fail under vibration (IEC 60068-2-6). However, industrial-grade USB cables with dual screw locks or locking Type-C connectors eliminate mechanical back-out. Manufacturers like Goobuy engineer their USB modules specifically for AGV chassis vibration, offering reliability comparable to M12 or FAKRA connectors in indoor environments.

Q3: How does USB latency compare to MIPI CSI-2 for visual servoing?

A: MIPI CSI-2 offers the lowest possible latency (sub-1ms) as it connects directly to the SoC’s ISP, making it ideal for high-speed robotic arm feedback loops (>100Hz). USB 3.0 introduces variable latency (typically 10-30ms) due to OS scheduling and protocol overhead. While USB is excellent for navigation (VSLAM) and obstacle avoidance, MIPI is preferred for high-frequency, real-time end-effector control.

Q4: Can I run GMSL2 and USB cameras simultaneously on NVIDIA Jetson?

A: Yes, this is known as a "Hybrid Vision Architecture." A common configuration uses the Jetson’s CSI lanes for GMSL2 navigation cameras (long-range, outdoor) while utilizing the USB 3.0 ports for secondary sensors like depth cameras, rear-view monitoring, or barcode scanners. This approach optimizes the system BOM by avoiding expensive SerDes hardware for short-range, non-critical links.

Q5: Does GMSL2 require custom drivers for NVIDIA JetPack 6?

A: Yes. Unlike USB cameras which use the universal Linux UVC driver, GMSL2 cameras require a custom kernel driver and a specific Device Tree Overlay (DTO) matching the exact sensor, serializer, deserializer, and carrier board combination. Major OS upgrades (e.g., JetPack 5 to 6) often break these drivers, requiring significant NRE and regression testing to restore functionality.

Q6: What is the best camera interface for compact medical devices or internal monitoring?

A: For space-constrained internal applications (e.g., cargo monitoring inside a delivery bot or documentation cams on a medical cart), USB 2.0/3.0 is often superior due to compatibility with x86/Android hosts. Compact modules, such as the Goobuy UC-501 usb camera Series, allow engineers to integrate vision into tight spaces (15x15mm) without the bulk of GMSL deserializer boards or the length limits of MIPI FPC cables.

Q7: What is the fastest way to prototype Visual SLAM on ROS 2?

A: Industrial USB is the fastest interface for prototyping. It allows engineers to map a camera to a ROS 2 node (e.g., usb_cam) in minutes without kernel compilation. GMSL2 and MIPI interfaces often require weeks of "bring-up" time to resolve clocking, power sequencing, and driver conflicts before an image can be published to the ROS topic.

Q8: What is the maximum cable length for USB 3.0 vs GMSL2 in robotics?

A: GMSL2 supports cable runs of 15 meters (50 feet) or more using coaxial cable with no signal degradation. USB 3.0 is generally limited to 3 meters (10 feet) for passive cables, or up to 10 meters with active repeater cables (though these add cost and failure points). For robots requiring cable runs exceeding 5 meters, GMSL2 or Ethernet are the mandatory choices.

About Goobuy Shenzhen Novel Electronics Limited provides industrial-grade camera modules for the Physical AI era. From robotics to medical devices, we bridge the gap between NVIDIA/Qualcomm chips and the real world.

View goobuy camera products here https://www.okgoobuy.com/products.html

View original raw testing video of goobuy cameras on our youtube channels here

https://www.youtube.com/@okgoobuy/featured

Follow and view Goobuy linkedin Industry analysis and professional articles here https://www.linkedin.com/in/novelvisiontech/