Goobuy custom STARVIS camera modules offer IMX585/IMX482/IMX675/IMX327 options with USB, HDMI and AHD interfaces for robotics, night vision and industrial AI. OEM optics, firmware and board-level customization included

Goobuy custom STARVIS camera modules deliver tailored imaging solutions built on Sony STARVIS and STARVIS 2 sensors—such as IMX585, IMX482, IMX675, IMX662 and IMX327—across USB, HDMI and MIPI CSI-2 interfaces. Designed for industrial night vision, robotics, UAV inspection, energy-sector monitoring and embedded AI devices, these modules are engineered to meet project-specific requirements in optics, board size, firmware, temperature range and long-term reliability. From feasibility review to EVT/DVT/PVT and mass production, Goobuy provides a complete OEM/ODM development workflow for 1080p–4K+ low-light camera systems.

Note: shenzhen novel electronics limited had launched and are sale following Starvis starlight night vision camera module well

(1)imx291 USB camera,

(2)imx415 USB+HDMI camera module,

(3)imx335 USB3.0 camera,

(4)imx678 HDMI camera module,

(5)imx678 USB camera,

(6)imx307 USB camera,

(7)imx385 USB camera,

(8)imx462 USB camera

if you want to extend and use other Starvis cmos sensor model to custom-made 100% new personalized night vision camera module specially for your project, please read this product page carefully

Custom Sony STARVIS Camera Modules — USB / HDMI / AHD (IMX585 · IMX482 · IMX675 · IMX317 · IMX327 · IMX264)

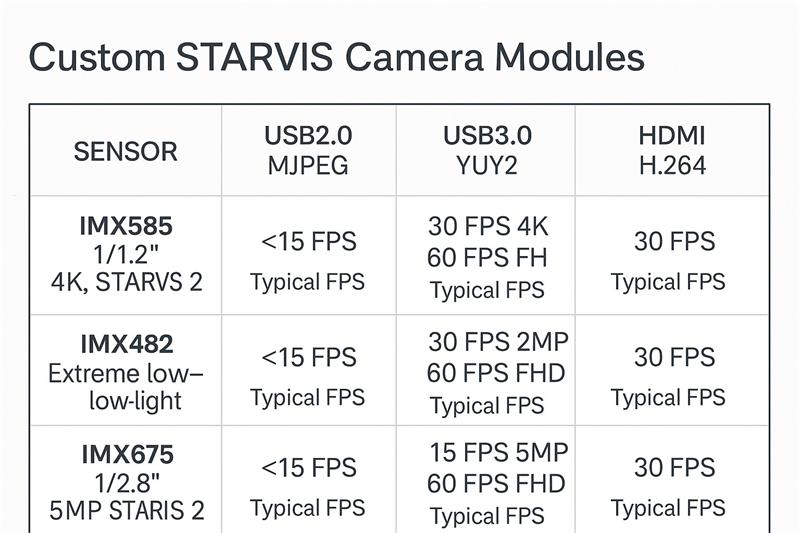

Supported Sensors: Sony STARVIS & STARVIS 2 (IMX585 / IMX482 / IMX675 / IMX662 / IMX327 / IMX317 / IMX264)

Interfaces: USB2.0 / USB3.0 / HDMI

Resolutions: 1080p → 4K (2MP–8MP+)

Board Formats: 32×32 mm, 38×38 mm, FPC designs, custom shapes

Optics: M12 or CS-mount; wide, low-distortion, IR-pass/IR-cut, F1.0–F2.8 options

Controls: Trigger, strobe, sync, GPIO, OSD, ISP tuning

Environmental: –20°C to +70°C, vibration-resistant, industrial durability

Compliance: CE / FCC / RoHS certified builds

OEM Support: Firmware customization, CAD design, EVT/DVT/PVT workflow, white-label branding

Featuring IMX585, IMX482, IMX675 with USB, AHD, & HDMI Interfaces

From Sensor to Solution: Custom-Engineered Sony STARVIS Camera Modules

Your most complex imaging challenges have a solution. We specialize in developing high-performance, application-specific camera modules built on the industry-leading Sony STARVIS and STARVIS 2 sensor platforms. Whether your project demands ultimate 4K low-light performance, extreme NIR sensitivity, or a perfect balance of resolution and cost, our engineering team is ready to deliver a vision solution, not just a component.

[High-quality hero video or dynamic image here. It should showcase a variety of custom-designed modules, the engineering process (e.g., a technician working on a board), and impressive low-light performance footage.]

More Than a Manufacturer, We Are Your Vision Partner

In a market of off-the-shelf hardware, we provide a decisive advantage: deep engineering expertise and an end-to-end partnership. We enable you to build a better, more competitive product by providing a camera module that is perfectly optimized for its task.

1. Deep Sensor Expertise

We don't just read datasheets; we understand the nuanced performance of each sensor. We know that the IMX585 is the choice for unparalleled 4K vision in darkness, the IMX482 is the specialist for extreme sensitivity with its massive pixels, and the IMX675 offers the perfect blend of 5MP resolution and STARVIS 2 performance. We guide you to the right sensor to meet your performance and budget targets.

2. End-to-End Development Capabilities

Our in-house, full-stack capabilities mean we control every critical variable of your camera's performance.

3. Agile Prototyping & Scalable Production

Our agile development process is designed to accelerate your time-to-market. We move quickly from design to functional prototype for your evaluation. Once validated, our ISO 9001-certified quality management and robust supply chain ensure a seamless transition from a single unit to mass production, delivering consistent quality at any scale.

You send a short brief or use our Spec Builder. We return:

Spec Builder (what we need):

Use case (UAV/Robot/Energy) · Target sensor(s) · Interface (USB/HDMI/MIPI) · Output format (MJPEG/YUY2/H.264) · Resolution & FPS targets · Lens mount & FOV · NIR/HDR needs · Working distance/DoF · Min object size (pixels) · Host OS/CPU (Jetson/RPi/x86) · Power budget · Board size/housing constraints (32×32/38×38/custom) · Temperature/vibration · Compliance (CE/FCC/RoHS) · Quantities & timeline.

Deliverables: EVT boards, basic datasheet & pinout, UVC control map, 2D DXF & 3D STEP.

Deliverables: DVT report、revised drawings、sample footage(night/NIR/HDR)

This is an excellent selection for comparison. As of 2025, these five Sony image sensors represent a range of flagship and classic products in the security and machine vision industries. Their core differences are indeed centered on their night vision capabilities, which stem from their different technology generations, sensor sizes, and pixel designs.

Below is a detailed parameter comparison and an in-depth analysis of their night vision performance.

• IMX585 (4K STARVIS 2)

Best for 4K industrial night vision, AI analytics, security and energy-sector monitoring. Excellent low-light and HDR, ideal for harsh outdoor or dim environments.

• IMX482 (1080p, 5.86µm large pixels)

Extreme low-light sensitivity for inspection robots, tunnels, substations, UAV inspections and long-range NIR imaging.

• IMX675 (5MP STARVIS 2)

Balanced performance for robotics, AMRs/AGVs and embedded devices needing a mix of HDR, efficiency and high image quality.

• IMX662 (1080p STARVIS 2)

High sensitivity + low noise + excellent efficiency, great for cost-optimized industrial devices, smart terminals and AI edge boxes.

• IMX327 (1080p classic STARVIS)

Proven, stable and cost-effective; widely adopted in millions of industrial cameras, ideal for mass-market embedded designs.

|

Parameter Category |

IMX585 (4K Low-Light Flagship) |

IMX482 (1080p Sensitivity King) |

IMX675 (5MP Mainstream Benchmark) |

IMX662 (1080p Technology Benchmark) |

IMX327 (1080p Classic Baseline) |

|

Core Technology |

STARVIS 2 |

STARVIS (1st Gen) |

STARVIS 2 |

STARVIS 2 |

STARVIS (1st Gen) |

|

Resolution |

8.29 MP (4K) |

2.13 MP (1080p) |

5.12 MP |

2.13 MP (1080p) |

2.13 MP (1080p) |

|

Sensor Size |

Type 1/1.2" (13.12 mm) |

Type 1/1.2" (13.12 mm) |

Type 1/2.8" (6.46 mm) |

Type 1/2.8" (6.46 mm) |

Type 1/2.8" (6.46 mm) |

|

Pixel Size |

2.9 µm |

5.86 µm (Massive) |

2.0 µm |

2.9 µm |

2.9 µm |

|

Dynamic Range Tech |

Single Exposure HDR |

DOL-HDR |

Single Exposure HDR |

Single Exposure HDR |

DOL-HDR |

|

SNR1s Index* |

Extremely Low (Top Tier) |

Extremely Low (Top Tier) |

Lower |

Low |

Standard |

*SNR1s: Sony's low-light performance index. The lower the value, the darker the environment in which the sensor can maintain a clear, usable image—meaning its night vision capability is stronger.

Our Proven 6-Step Development Process

We make custom development transparent, predictable, and efficient.

step 1 Discovery & Consultation: We begin by understanding your application, performance goals, and constraints.

step 2 Solution Architecture & Proposal: Our engineers design a technical solution and provide a detailed proposal, including specifications and project milestones.

step 3 Design & Development: Upon approval, our hardware, software, and mechanical teams begin the core engineering work.

step 4 Prototyping & Validation: We build and deliver the first functional prototypes for your in-house testing and validation.

step 5 Optimization & Client Feedback: We work collaboratively with your team to refine ISP tuning and make any necessary adjustments based on your feedback.

step 6 Mass Production & Lifecycle Support: We manage the full production lifecycle and provide ongoing technical support for your product.

Frequently Asked Questions

Q1. What advantages do Goobuy custom STARVIS camera modules offer compared with standard off-the-shelf USB or MIPI cameras?

A1. Goobuy custom STARVIS camera modules provide full OEM customization in sensor selection, optics, board size, interface (USB/HDMI/MIPI), firmware, temperature rating and reliability—making them suitable for robotics, energy monitoring, UAV inspection and professional embedded AI devices.

Q2. Which interface should I choose for my project: USB, HDMI or MIPI CSI-2?

A2. USB is ideal for rapid integration with PCs, Jetson or Raspberry Pi; MIPI CSI-2 is best for embedded systems needing low latency and compact form factor; HDMI suits monitors, NVRs or high-stability vision systems. Goobuy engineers can match the interface to your hardware constraints and performance targets.

Q3. Can Goobuy develop a custom STARVIS camera that works across extreme environmental conditions?

A3. Yes. Goobuy supports industrial-grade builds with –20°C to +70°C operation, vibration-resistant design, rugged connectors and sealed housings. These configurations are widely used in energy infrastructure, outdoor robotics and UAV inspection tasks.

Q4. What optical customization options are available?

A4. Goobuy offers M12 or CS-mount lenses, low-distortion lenses, IR-pass/IR-cut filters, F1.0–F2.8 apertures, telephoto or ultra-wide lenses, and NIR-optimized optics. Optical tuning can be matched to IMX585/IMX482/IMX675/IMX327 or other STARVIS sensors.

Q5. How long does a custom STARVIS USB/HDMI/MIPI camera project take from concept to mass production?

A5. Typical workflow: Feasibility (48 hours) → EVT (3–6 weeks) → DVT (4–8 weeks) → PVT → Mass Production. Goobuy provides CAD files, firmware tuning, testing reports and life-cycle support throughout each stage.

Q6: "Do you charge NRE (Non-Recurring Engineering) fees?" A: For minor modifications (e.g., cable length, lens change), there is Zero NRE. For full PCB redesigns, we charge a refundable NRE fee, which is credited back once your order volume reaches a target quantity (e.g., 1000-3000 units).

Q7: "Can you integrate multiple STARVIS sensors onto one board (Stereo Vision)?" A: Yes. Our engineering team has extensive experience in Synchronized Multi-Sensor designs (Dual IMX462 or IMX678) for stereo depth sensing and 360-degree panoramic stitching on NVIDIA Jetson platforms.

Q8: "Do you provide ISP tuning services for color accuracy?" A: Yes. We have an in-house Image Quality (IQ) Lab. We can fine-tune the ISP parameters (AWB, CCM, Gamma) to match your specific lighting environment (e.g., medical operating rooms or traffic tunnels).

Q9. Can Goobuy support long-term production and white-label branding for custom STARVIS modules?

A6. Yes. Goobuy offers white-label manufacturing, long-term component planning, lifecycle management, and MP scaling for custom STARVIS camera modules, ensuring supply stability for robotics, industrial OEMs and global device manufacturers.

Learn how to custom-made starvis usb camera guide, read this article here

Custom STARVIS USB Cameras: Complete Project Guide

know more information about these starvis cmos sensor

Detailed Comparison of IMX585, IMX482, IMX327, IMX662, and IMX675

open and read this blog STARVIS sony sensor compare: IMX678 vs IMX385 vs IMX585 vs IMX327

Know our core advantage and factory, click and read here

Let's Build Your Next-Generation Vision System

Your project deserves more than a generic camera. It deserves a perfectly tailored vision solution. Contact our engineering team today for a free, no-obligation consultation to discuss your technical requirements and project goals.reach our engineering team directly at office@okgoobuy.com

Relative Blogs and product application Articles

1, IMX585 vs IMX678: Industrial Camera Sensor Guide

2, STARVIS sony sensor compare: IMX678 vs IMX385 vs IMX585 vs IMX327

3, Sensor Comparison: IMX678 vs IMX385 VS IMX585 VS IMX327 for Night Vision Performance STARVIS

4, STARVIS IMX307 vs IMX385 vs IMX585 vs IMX678 vs GC2053 Night Vision Performance compare